Product Main Parameters

| Parameter | Value |

|---|---|

| System Voltage | 40.5kV |

| Rated Current | Up to 2000A |

| Frequency | 50/60Hz |

Common Product Specifications

| Item | Data |

|---|---|

| Rated Voltage | 40.5kV |

| Rated Current of Main Bus Bar | 1250, 1600, 2000, (2500) A |

Product Manufacturing Process

The manufacturing process of withdrawable switchgear involves precise engineering and advanced assembly techniques. According to authoritative sources, the process begins with the design of the switchgear components, emphasizing the integration of mechanical and electrical systems. The production involves creating modular components that are tested for mechanical and electrical reliability. The testing ensures compliance with international standards, with rigorous quality checks at each stage of production. This meticulous approach ensures that the switchgear meets high-performance criteria, offering durability and safety in operation.

Product Application Scenarios

Withdrawable switchgear is essential in dynamic environments where safety and operational continuity are paramount. As highlighted in industry studies, these systems are extensively employed in industrial plants and utility sectors to manage complex power distribution networks. Their modularity allows for customized configurations, catering to unique power management needs, and ensuring minimal disruption during maintenance or upgrades. This flexibility positions withdrawable switchgear as a critical component for ensuring operational efficiency and adaptability in various high-demand settings.

Product After-Sales Service

Our after-sales service includes a comprehensive warranty, on-site technical support, and a dedicated helpline to address any issues swiftly. We ensure that our clients have full access to service resources for peace of mind.

Product Transportation

Robust packaging and trusted logistics partners ensure safe delivery of your switchgear, with tracking options available to monitor shipment progress from our facility to your location.

Product Advantages

- Enhanced safety due to modular breaker design.

- Efficient maintenance with minimal system downtime.

- Flexibility to scale and adapt to changing requirements.

- Effective fault isolation through compartmentalization.

Product FAQ

- What is the main advantage of withdrawable switchgear?

Withdrawable switchgear offers enhanced safety and ease of maintenance. It allows for circuit breakers to be inserted or removed without exposing operators to live components, minimizing the risk of electrical hazards.

- How does withdrawable switchgear improve maintenance efficiency?

This type of switchgear allows for quick replacement or maintenance of circuit breakers without disrupting the entire system, significantly reducing downtime and maintenance costs.

- What are the primary applications of withdrawable switchgear?

Withdrawable switchgear is used in industrial plants, utilities, and commercial buildings where complex power distribution systems require safety, flexibility, and reliability.

Product Hot Topics

- The Growing Demand for Withdrawable Switchgear

The demand for withdrawable switchgear is on the rise due to its adaptability and safety features. Wholesale distributors are increasingly looking to stock these products to meet the evolving needs of industrial and utility applications. The modular design caters to a range of electrical requirements, making it a versatile choice for businesses aiming to enhance their power distribution systems.

- Safety Considerations in Withdrawable Switchgear Design

Safety is paramount in the design of withdrawable switchgear. Manufacturers focus on creating switchgear that provides isolation from live components to protect technicians and operators. This emphasis on safety makes it a preferred option in settings where operational hazards must be minimized, reinforcing its value in wholesale and retail markets.

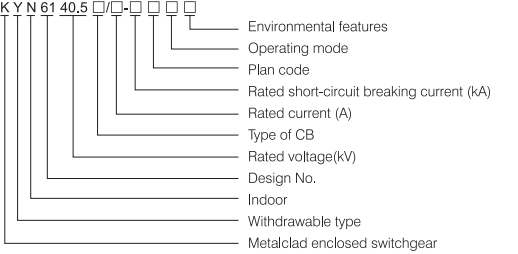

Image Description