Product Main Parameters

| Parameter | Specification |

|---|---|

| Voltage Rating | 3, 6, 10KV |

| Frequency | 50Hz |

| Protection Level | IP3x |

| Operation Mode | Manual and Electric |

| Dimensions | Customizable |

Common Product Specifications

| Specification | Details |

|---|---|

| Primary Material | Copper/Aluminum |

| Core Type | Laminated Silicon Steel |

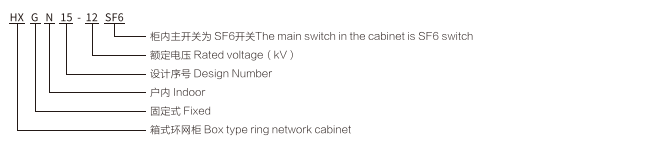

| Main Switch | SF6 Switch |

Product Manufacturing Process

The manufacturing of high voltage switchgear with transformer winding involves precise engineering and state-of-the-art technology. According to authoritative sources, the process begins with the selection of high-grade copper or aluminum for windings, ensuring optimal conductivity and efficiency. These materials are wound around a laminated silicon steel core, providing a minimal reluctance path for the magnetic field. Advanced CNC machines rivet the cabinet components, ensuring a robust structure with IP3x protection. The assembly integrates ABB original parts or high-quality equivalents, certified to IEC62271-200:2003 and GB3906 standards. This meticulous process results in durable, low-maintenance equipment suitable for diverse industrial applications.

Product Application Scenarios

High voltage switchgear with transformer winding is essential in various energy distribution settings. It is utilized in three-phase AC power systems to safely receive and distribute electrical energy, particularly in environments requiring frequent operations. As noted in authoritative industry publications, its application spans industrial and civil cable networks, power terminals, urban residential areas, and secondary power stations. Its reliable performance in harsh conditions, including high altitudes and temperature variations, makes it suitable for mining enterprises, airports, subways, power stations, and hospitals. These scenarios require efficient energy distribution with minimal power loss, a distinctive capability of this high voltage switchgear.

Product After-Sales Service

Our dedicated after-sales service ensures optimal product performance and customer satisfaction. We offer comprehensive support, including installation guidance, maintenance tips, and expert consultations to address any technical issues promptly.

Product Transportation

Ensuring safe and secure delivery, all products are dispatched in robust packaging, suitable for domestic and international transport. We partner with reliable logistics providers to facilitate prompt and safe arrival to your specified location.

Product Advantages

- High Efficiency: The advanced transformer winding enhances energy conversion, reducing resistive losses.

- Reliability: Built with top-grade materials and tested for performance and safety under varying conditions.

- Customizable: Flexible dimensions and configurations to meet specific project requirements.

- Cost-effective: Competitive wholesale pricing with superior performance and low maintenance requirements.

Product FAQ

- What is transformer winding?

Transformer winding refers to coils within a transformer that transfer electrical energy via electromagnetic induction. They are crucial in adjusting voltage levels for power distribution.

- Why choose wholesale switchgear?

Purchasing switchgear at wholesale prices ensures cost savings without compromising quality, making it ideal for large projects.

- How do I ensure the longevity of my transformer winding?

Regular maintenance, proper installation, and adherence to specified operating conditions are key to extending the life of transformer windings.

- Can this switchgear be used in high altitude areas?

Yes, our high voltage switchgear is designed to operate efficiently at altitudes up to 2000m.

- Is special training required for operation?

Basic training on the operation and safety protocols is recommended to ensure safe and effective use.

- What materials are used in the winding process?

We use high-conductivity copper or aluminum, known for their excellent electrical properties, in the winding process.

- How does the product handle temperature variations?

Equipped to operate in temperatures from -25°C to 45°C, the switchgear handles environmental changes effectively.

- What type of maintenance is required?

Periodic inspections and cleaning of components will help maintain optimal functionality.

- Can the configuration be customized?

Yes, we offer customizable configurations to suit different power distribution needs and specifications.

- What makes your switchgear eco-friendly?

Utilizing innovative materials and designs, our switchgear reduces energy waste and promotes sustainable energy use.

Product Hot Topics

- Impact of Advanced Transformer Winding on Efficiency

Transformer winding plays a vital role in energy efficiency. By optimizing the design and materials used, substantial reductions in resistive losses can be achieved, leading to enhanced overall system performance. Our switchgear incorporates the latest advancements in winding technology, ensuring minimal energy waste and improved operational efficacy.

- Sustainability in Switchgear Manufacturing

Today's energy demands necessitate sustainable manufacturing practices. Our commitment is evident in our use of recyclable materials and energy-efficient production processes. By focusing on sustainable development, we contribute to global energy transition efforts while delivering superior quality switchgear at wholesale prices.

- Challenges in Transformer Winding Design

Designing transformer windings involves various challenges, including thermal management and material resilience. By employing cutting-edge technology and rigorous quality control, we address these challenges, ensuring stable performance and longevity even under demanding conditions.

- Wholesale Advantages in Power Distribution Projects

Securing switchgear at a wholesale level significantly benefits large-scale projects. It provides cost savings, flexibility in supply, and ensures consistent quality, essential for robust energy infrastructures.

- Innovation Trends in Transformer Technology

The transformer industry continuously evolves with innovations aimed at enhancing efficiency and reliability. Our R&D initiatives focus on integrating these innovations into our products, maintaining a competitive edge in the wholesale market.

- Global Needs for Reliable Power Solutions

The demand for reliable power solutions continues to grow worldwide. Our switchgear, featuring advanced transformer winding, meets this demand, offering secure energy distribution across various sectors.

- Customizing Switchgear for Diverse Applications

Different applications demand unique configurations. Our ability to tailor switchgear to specific needs ensures optimal performance, whether in industrial, commercial, or urban settings.

- Understanding the Electrical Safety of Switchgear

Electrical safety is paramount in all power distribution systems. Our switchgear, compliant with international standards, incorporates fail-safe mechanisms and robust materials, ensuring superior safety and reliability.

- The Evolution of Transformer Winding Materials

From traditional copper to modern superconducting materials, the evolution in transformer winding materials has revolutionized energy distribution. These advancements contribute to higher efficiencies and lower operational costs.

- Role of Feedback in Product Development

Feedback from customers is invaluable in refining our products. We actively engage in feedback loops, which inform our R&D and drive continuous improvement in our switchgear offerings.

Image Description