Trusted Manufacturer of 3000 kVA Transformers

Product Main Parameters

| Parameter | Value |

|---|---|

| Phase | Three |

| Service Voltage | 6-35kV |

| Rated Capacity | 3000 kVA |

Common Product Specifications

| Model No. | Connection | Impedance Voltage (%) | No-load Current (%) | Dimensions (mm) | Weight (Kg) |

|---|---|---|---|---|---|

| SG10-3000/10 | Y,yn0 D,yn11 | 1.1 | 3.2 | 1350x1550x1700 | 3950 |

Product Manufacturing Process

The manufacturing process of a 3000 kVA transformer involves several critical steps to ensure high quality and reliability. Initially, high-grade electrical steel sheets are stacked to form the transformer core, which is carefully insulated and wound with copper or aluminum wire to create the primary and secondary windings. Advanced precision equipment is used to ensure tight and consistent winding, minimizing losses and maximizing efficiency. The assembly is then thoroughly tested for electrical performance before being enclosed in a robust protective casing. Quality control measures are implemented at every stage, with inspections and tests conforming to international standards like IEEE and IEC. The result is a durable transformer that effectively manages voltage transformation while ensuring safety and durability.

Product Application Scenarios

The 3000 kVA transformers are instrumental in various industrial and commercial applications. These transformers are well-suited for distribution networks, providing essential voltage regulation and power distribution in large facilities such as manufacturing plants, data centers, and hospitals. Their robust design allows them to operate efficiently in harsh environments like mines and chemical plants. Additionally, transformers of this capacity are ideal for substations within utility grids, converting high-voltage power from transmission lines to the lower voltages needed for residential and commercial distribution. Their versatility and reliability make them a cornerstone of modern power systems, ensuring the safe and efficient delivery of electricity.

Product After-Sales Service

We offer comprehensive after-sales support to all our customers. Our services include installation guidance, regular maintenance check-ups, and timely troubleshooting assistance. We ensure that our technical support team is available to address any issues or concerns, ensuring optimal performance and longevity of the transformer.

Product Transportation

Our transformers are packaged securely to ensure safe transit. We collaborate with reliable logistics partners specializing in handling heavy equipment to provide timely and efficient delivery to the project site, both domestic and international.

Product Advantages

- High Efficiency: Over 95% efficiency, reducing energy losses and operational costs.

- Robust Design: Durable construction with advanced materials ensures long lifespan.

- Cost-Effective: Competitive pricing without compromising quality.

- Compliance: Meets rigorous international standards such as IEEE and IEC.

Product FAQ

- What maintenance is required for a 3000 kVA transformer?

Regular inspections for physical damage, checking electrical connections, monitoring temperature and fluid levels, and testing insulation resistance are vital for maintaining a 3000 kVA transformer. A professional service provider should perform these tasks periodically to ensure optimal performance and longevity.

- How long does a 3000 kVA transformer typically last?

With proper maintenance, a 3000 kVA transformer can last 20 to 30 years. However, its lifespan can vary based on operational conditions, environmental factors, and the quality of ongoing maintenance services.

- Can a 3000 kVA transformer operate in extreme environments?

Yes, these transformers are designed for versatility and can operate efficiently in harsh conditions, such as high temperatures and corrosive environments, provided they are equipped with appropriate protective enclosures and cooling systems.

- What safety features are included in a 3000 kVA transformer?

Safety features include robust insulating materials, protective devices like circuit breakers and fuses, and advanced monitoring systems to prevent overloads and electrical faults, ensuring safe operation.

- How is a 3000 kVA transformer installed?

Installation requires careful planning, considering factors like site location, ventilation, access for maintenance, and compliance with local electrical codes. It is advisable to engage experienced professionals for installation to ensure adherence to safety standards and optimal functionality.

- What are the power loss rates in a 3000 kVA transformer?

Power loss in a transformer occurs mainly through heat dissipation, with copper losses in the winding and core losses due to hysteresis and eddy currents. Typically, these losses are minimized through design optimizations to achieve efficiency above 95%.

- What happens during a power surge through a 3000 kVA transformer?

Transformers are designed to handle occasional power surges through features such as surge arresters and protective relays. However, frequent or prolonged surges can cause overheating and potential damage, so additional voltage regulation may be required.

- How is the efficiency of a 3000 kVA transformer measured?

Efficiency is measured by comparing the input power to output power, considering losses in the form of heat, with efficiency rates typically exceeding 95%. Regular efficiency testing ensures the transformer operates within optimal parameters.

- Are there environmental considerations for 3000 kVA transformers?

Modern transformers are built to minimize environmental impact, using eco-friendly insulating materials and adhering to stringent environmental protection standards. Additionally, dry-type transformers are available for applications where oil-based models pose environmental risks.

- Can a 3000 kVA transformer be customized?

Yes, manufacturers can offer customization options to meet specific client requirements, such as altering voltage ratings, connection types, or incorporating special features for unique operational environments.

Product Hot Topics

- Advancements in 3000 kVA Transformer Efficiency

Manufacturers are continually seeking ways to enhance transformer efficiency, utilizing new materials and innovative design strategies. The integration of AI and IoT technologies has enabled predictive maintenance and performance optimization, ensuring transformers operate at peak efficiency and reliability.

- Impact of 3000 kVA Transformers on Industrial Power Systems

The 3000 kVA transformers play a crucial role in modern industrial power systems, allowing for the efficient distribution and regulation of electrical power. Their robust construction and reliability make them indispensable in demanding environments, supporting the continuous operation of critical infrastructure.

- The Role of 3000 kVA Transformers in Renewable Energy Integration

With the surge in renewable energy generation, 3000 kVA transformers have become essential in facilitating the integration of solar and wind power into existing grids. By adapting to fluctuating input levels, they ensure stable and efficient energy distribution across diverse networks.

- Challenges in 3000 kVA Transformer Maintenance

Maintenance of a 3000 kVA transformer presents unique challenges, requiring specialized knowledge and equipment. Regular monitoring and advanced diagnostic tools help in identifying and addressing potential issues before they lead to system failures.

- Safety Standards for 3000 kVA Transformers

Strict adherence to safety standards is paramount for the operation of 3000 kVA transformers. Compliance with international standards ensures these transformers meet rigorous criteria for reliability and safety, protecting both equipment and personnel.

- Innovations in Transformer Cooling Techniques

Cooling technology advancements have significantly improved transformer performance. Modern systems like forced-air cooling and the introduction of high-efficiency cooling mediums ensure temperature control, reducing the risk of overheating and extending the transformer’s life.

- Environmental Impact of Transformer Design Choices

Manufacturers are focusing on reducing the environmental impact of transformers by selecting eco-friendly materials and designs. Dry-type transformers, for instance, offer a safer, oil-free alternative for installations sensitive to environmental considerations.

- Cost-Effective Solutions with 3000 kVA Transformers

The introduction of cost-effective materials and streamlined manufacturing processes has allowed manufacturers to offer high-quality 3000 kVA transformers at competitive prices, making them accessible for a broader range of applications without compromising performance.

- Customization Options for 3000 kVA Transformers

Manufacturers provide various customization options to cater to specific operational requirements. From altering voltage and capacity specifications to integrating specialized protective features, customers can tailor transformers to fit their precise needs.

- Future Trends in Transformer Technology

The future of transformer technology is poised for transformative advancements with the integration of smart technologies and materials science breakthroughs. Innovations such as self-healing insulation and real-time performance monitoring are set to redefine efficiency and reliability standards in the industry.

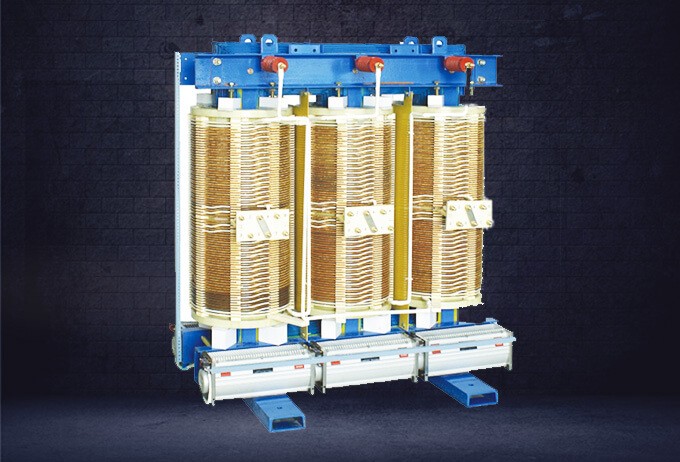

Image Description

There is no picture description for this product