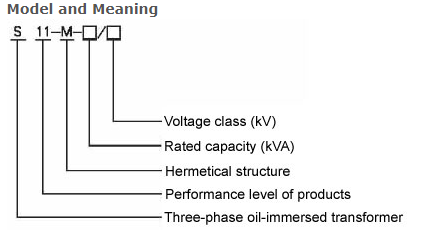

Supplier of Hermetically Sealed Oil Filled Transformers

Product Main Parameters

| Type | Rated Capacity (KVA) | Voltage Combination (KV) | No-load Losses (W) | Load Losses (W) | No-load Current (%) | Short-circuit Impedance (%) |

|---|---|---|---|---|---|---|

| S11 30 | 30 | 6-11 | 100 | 600 | 2.3 | 4.0 |

| S11 1000 | 1000 | 15-22 | 1130 | 11330 | 0.7 | 6.0 |

Common Product Specifications

| Parameter | Specification |

|---|---|

| Phase | Three |

| Service Voltage | 6-35kV |

| Rated Capacity | 30-10000kVA |

Product Manufacturing Process

The manufacturing process of hermetically sealed oil-filled transformers involves several critical stages. Initially, the core and windings are meticulously assembled following precise engineering designs. The assembly is then encased in a robust, sealed tank, which is welded carefully to ensure airtightness. High-grade insulating oil is filled into the tank, serving as both an insulator and coolant. Modern techniques, including computer-aided design (CAD) and finite element analysis (FEA), are employed to enhance the structural and thermal performance of the transformers. Rigorous testing phases are conducted to guarantee compliance with IEC and GB standards, ensuring each unit’s reliability and efficiency.

Product Application Scenarios

Hermetically sealed oil-filled transformers have diverse applications across multiple sectors. In the utility sector, these transformers play a pivotal role in power distribution networks, providing reliable voltage transformation needed for efficient electricity transmission. Industries requiring uninterrupted power supply, such as manufacturing and petrochemical plants, rely heavily on these transformers for their robustness and low maintenance needs. Additionally, renewable energy installations, including solar and wind farms, benefit from their resilience in harsh environmental conditions, ensuring seamless power integration into the grid.

Product After-Sales Service

Our commitment to customer satisfaction extends beyond the sale, providing comprehensive after-sales support that includes technical assistance, regular maintenance, and troubleshooting. We prioritize addressing client queries promptly and offer tailored service packages to ensure long-term operational efficiency of all supplied hermetically sealed oil-filled transformers.

Product Transportation

Transportation of hermetically sealed oil-filled transformers is handled with utmost care to ensure their integrity upon delivery. Our logistics team works with reputable carriers to ensure timely and safe transport, utilizing custom packaging solutions that minimize transit-related risks. We provide real-time tracking and insurance options for added assurance.

Product Advantages

- Enhanced Insulation and Cooling

- Protection Against Environmental Factors

- Reduced Maintenance Requirements

- Improved Reliability and Safety

- Avoidance of Oil Oxidation

FAQ

What is the lifespan of a hermetically sealed oil-filled transformer?

Typically, these transformers boast a lifespan of 20 to 30 years, thanks to their superior design and materials. The hermetic sealing greatly reduces the risk of environmental degradation, further extending operational life. Regular maintenance will ensure they continue to operate at peak efficiency throughout their life cycle.

What maintenance is required for these transformers?

While hermetically sealed transformers require less frequent maintenance than their non-sealed counterparts, periodic inspections to check oil purity and system integrity are recommended. Routine testing aids in early detection of potential issues, supporting uninterrupted service delivery.

How do these transformers manage to be energy efficient?

These transformers utilize advanced materials and design techniques to minimize energy losses through efficient insulation and cooling strategies. This results in reduced load and no-load losses, contributing to overall energy savings and environmental benefits.

Product Hot Topics

The Role of Hermetically Sealed Oil Filled Transformers in Modern Grids

The integration of hermetically sealed oil-filled transformers into modern electrical grids is instrumental in achieving enhanced reliability and efficiency. These transformers are pivotal in reducing energy losses and minimizing maintenance requirements, thereby lowering operational costs. With growing emphasis on sustainable and resilient power infrastructures, these transformers are increasingly favored for their adaptability and robust performance, supporting the transition towards cleaner energy solutions.

Challenges in Manufacturing Hermetically Sealed Transformers

Manufacturing hermetically sealed oil-filled transformers entails overcoming various technical challenges. Achieving an airtight seal without compromising the structural integrity of the transformer is critical. This demands precise engineering and high-quality materials to ensure the transformers can withstand operational stresses and environmental conditions. Despite these challenges, the benefits these transformers provide justify the complex manufacturing process, offering long-term reliability and superior performance in diverse applications.

Image Description