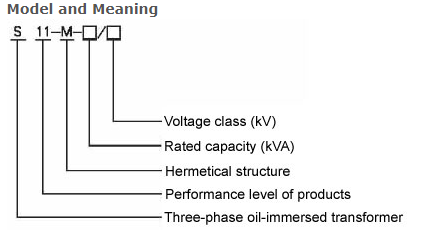

S11 Electric Oil Immersed AC Power Transformer Manufacturer

Product Main Parameters

| Type | Rated Capacity (KVA) | Connection Symbol | Voltage Combination (KV) | No-load Losses (W) | Load Losses (W) | No-load Current (%) | Short-circuit Impedance (%) | H.V Tapping Range | L.V |

|---|---|---|---|---|---|---|---|---|---|

| S11 | 30-2500 | Yyn0 or Dyn11 | 6-22 | 90-2700 | 660-20700 | 0.6-2.3 | 4.0-6.0 | ±5% or ±2×2.5% | 0.4 |

Common Product Specifications

| Material | Finish | Standard |

|---|---|---|

| Silicon Steel, Copper/Aluminum Windings | Oil-immersed, Sealed | GB 1094, IEC/60076 |

Product Manufacturing Process

Transformers are manufactured using state-of-the-art technology to ensure high-quality performance. The core is made from laminated silicon steel to reduce eddy current losses. Copper or aluminum windings are used for their excellent conductivity. Oil immersion provides insulation and cooling, aiding in the transformer's longevity and efficiency. Strict quality control at each production stage ensures product reliability and compliance with international standards. Authoritative studies highlight the importance of precise construction techniques to optimize magnetic properties and mechanical strength, contributing to overall transformer performance.

Product Application Scenarios

S11 AC power transformers are integral in various applications across industries. They are extensively used in power generation plants, stepping up voltage for efficient long-distance transmission. In substations, these transformers step down voltage, making electricity safer for residential and commercial use. Industries like aerospace, rail transit, and petrochemical also deploy these transformers for reliable power distribution and equipment protection. Authoritative sources stress the critical role of transformers in maintaining grid stability, ensuring energy efficiency, and accommodating increasing demand in renewable energy sectors.

Product After-Sales Service

Global Power Equipment provides comprehensive after-sales support, including technical assistance, maintenance services, and warranty options. Our customer service team ensures prompt responses, helping clients maximize their product's lifespan and performance.

Product Transportation

Our transformers are securely packaged and transported using specialized logistics services, ensuring safe and undamaged delivery to destinations worldwide. We comply with all shipping regulations to guarantee timely and efficient delivery.

Product Advantages

- Reliable performance and high efficiency

- Low noise and energy-saving features

- Compliance with international standards

Product FAQ

- Q1: What is the lifespan of the S11 transformer?

A1: The S11 transformer, manufactured by Global Power Equipment, typically has a lifespan of 20-30 years, depending on usage and maintenance. Regular inspections and servicing can prolong its life and ensure optimal performance. - Q2: How does oil immersion benefit the transformer?

A2: Oil immersion provides excellent insulation and cooling, enhancing the transformer's efficiency and reliability. It helps prevent overheating and extends the equipment's operational life. - Q3: Are your transformers compliant with international standards?

A3: Yes, as a leading manufacturer, our AC power transformers meet the Chinese GB standards and the international IEC standards, ensuring high-quality and reliable performance. - Q4: Can these transformers be used in outdoor conditions?

A4: Yes, the S11 transformer is designed for both indoor and outdoor use, withstanding various environmental conditions as specified in its operating conditions. - Q5: What voltage ranges do the S11 transformers support?

A5: The S11 transformers, manufactured by us, support a service voltage range of 6-35kV, catering to various distribution requirements. - Q6: How does the transformer contribute to energy saving?

A6: Our transformers feature low-loss cores and efficient windings, reducing overall energy wastage. This design contributes to lower operational costs and enhanced energy savings. - Q7: What are the installation requirements for these transformers?

A7: Installation should avoid fire, explosion hazards, chemical corrosion, and strong vibrations. Proper grounding and connection configurations are essential for safe performance. - Q8: How is maintenance handled for these products?

A8: Regular maintenance, including oil analysis, physical inspections, and electrical testing, ensures long-lasting performance. Our service team is available for detailed guidance and support. - Q9: Do you offer customization for specific applications?

A9: Yes, as a manufacturer, we offer custom solutions to meet specific industry needs, ensuring that our transformers fit precise operational requirements. - Q10: What is the warranty on your transformers?

A10: We provide a standard warranty period covering manufacturing defects and offer extended options. Our customer service team is ready to assist with any warranty-related inquiries.

Product Hot Topics

- Global Demand for Efficient Power Transformations

The need for efficient power distribution systems is growing globally, with manufacturers like Global Power Equipment leading the way in providing high-quality AC power transformers. These transformers are vital for modern infrastructure, helping countries enhance grid reliability and energy efficiency. The increasing integration of renewable energy sources necessitates transformers that can handle variable loads and ensure stable power supply. As the world pivots towards greener energy solutions, the importance of reliable transformers in the energy transition cannot be overstated. - Innovations in Transformer Technology

The world of transformer technology is constantly evolving. Manufacturers are leveraging advanced materials and design techniques to create more efficient, compact, and environmentally friendly transformers. Global Power Equipment is at the forefront of this innovation, continuously enhancing product quality and reducing ecological impact. These advancements are crucial for supporting the ever-increasing energy demands and maintaining sustainable development goals, making them a hot topic among industry experts and stakeholders. - Challenges in Global Transformer Supply Chain

The global supply chain for transformers faces challenges, from material shortages to logistical hurdles. Manufacturers, including Global Power Equipment, are navigating these challenges by optimizing production processes and enhancing supply chain resilience. As demand rises, especially in developing regions, ensuring a steady supply of high-quality transformers is crucial for meeting energy needs and supporting infrastructure projects worldwide. - The Role of Transformers in Renewable Energy Integration

As renewable energy sources become more prevalent, the role of transformers in integrating these sources into existing grids is increasingly important. Transformers like those produced by Global Power Equipment facilitate the seamless transition of power from generation sources like wind and solar into the grid, ensuring stability and efficiency. The contribution of such transformers is crucial for achieving cleaner energy goals and reducing carbon footprints globally. - Trends in Transformer Efficiency and Performance

Efficiency and performance remain central topics in transformer manufacturing. Advances in materials, such as high-grade core steel and innovative cooling techniques, are improving transformer performance and reducing losses. Global Power Equipment is among the manufacturers embracing these trends, offering products that meet stringent efficiency criteria while maintaining performance standards essential for modern energy systems. - Safety Standards and Compliance in Transformer Design

Adhering to strict safety standards and compliance regulations is non-negotiable in transformer manufacturing. Global Power Equipment ensures all its transformers meet or exceed international and local safety standards, providing peace of mind to clients and end-users. As regulations evolve, staying compliant while pushing for innovation is a challenging yet essential task for manufacturers in the industry. - Environmental Impact of Transformer Operations

The environmental impact of transformer operations is an ongoing concern for manufacturers and consumers alike. Companies like Global Power Equipment are committed to producing transformers that have minimal ecological footprints, utilizing eco-friendly materials and energy-efficient designs. Understanding and mitigating the environmental impact is central to sustainable manufacturing and energy distribution practices. - The Future of Smart Transformers in Smart Grids

Smart transformers are set to revolutionize power distribution in smart grids by offering dynamic control and monitoring capabilities. Manufacturers are investing in smart technologies to develop transformers that enhance grid reliability and efficiency. Global Power Equipment is poised to contribute significantly to this evolution, ensuring their transformers are compatible with future grid innovations. - Cost-Effectiveness of Transformer Investments

Investing in quality transformers is crucial for long-term cost savings and operational efficiency. The initial investment in high-performance transformers manufactured by leaders like Global Power Equipment can lead to substantial savings through reduced energy losses and extended operational life. Understanding the cost benefits and long-term value of such investments is a priority for businesses and infrastructure planners. - International Collaboration in Transformer Technology

Global collaboration in transformer technology enables manufacturers to share insights and advancements, driving innovation and improvements. Companies like Global Power Equipment engage in international partnerships to enhance their product offerings and adapt to varying market needs. This collaboration is essential for fostering global energy solutions and addressing universal challenges in power distribution.

Image Description