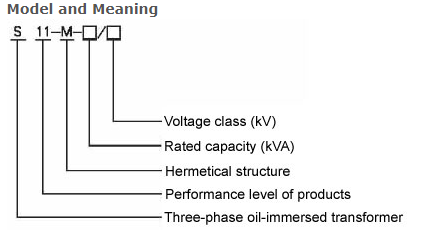

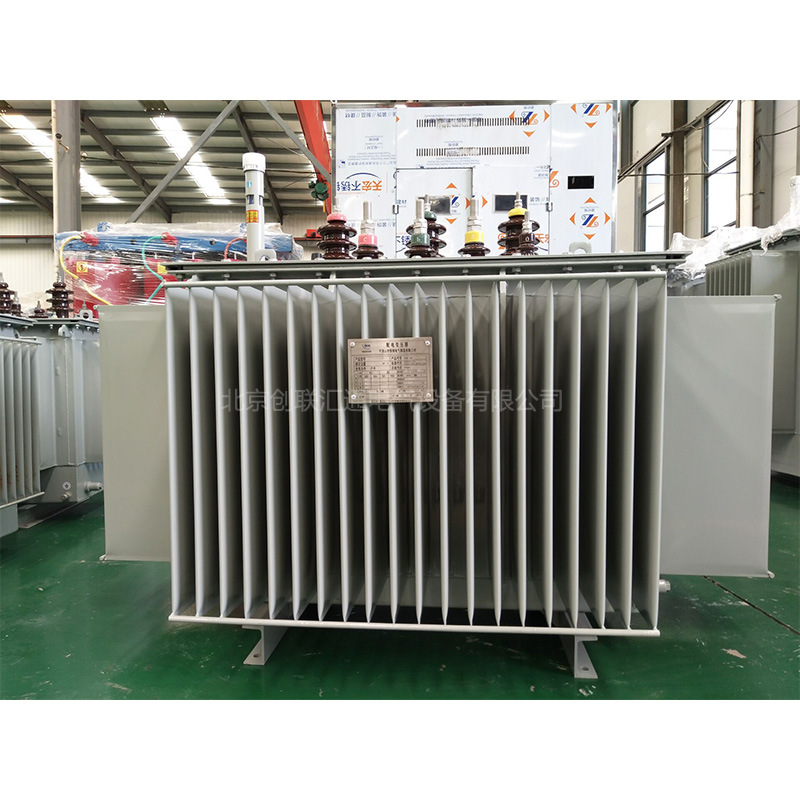

Reliable Supplier of Oil Immersed Self Cooled Transformer

Product Main Parameters

| Model Number | Phase | Service Voltage | Rated Capacity |

|---|---|---|---|

| S11 | Three | 6-35kV | 30-10000kVA |

Common Product Specifications

| Component | Description |

|---|---|

| Core | Thin steel laminations minimizing energy losses |

| Windings | Copper/Aluminum, primary and secondary windings |

| Transformer Oil | Refined mineral oil for insulation and cooling |

| Tank | Houses core and windings filled with oil |

| Conservator | Accommodates oil's thermal expansion |

| Radiators | Cooling fins to dissipate heat |

Product Manufacturing Process

Based on authoritative sources, the manufacturing process of oil immersed self cooled transformers involves several meticulous stages to ensure high quality. Initially, thin steel laminations are assembled to form the core, which is crucial for minimizing energy losses. Copper or aluminum conductors are then wound around the core to form the primary and secondary windings. Transformer oil, which plays a dual role of cooling and insulation, is added to the tank housing the core and windings. The conservator and radiators are assembled to aid the oil's thermal dynamics. Throughout this process, strict adherence to national and international standards, such as GB 1094 and IEC/60076, ensures the end product meets global reliability and efficiency benchmarks.

Product Application Scenarios

Oil immersed self cooled transformers are integral in various industrial and utility settings, primarily due to their efficiency in voltage transformation and reliable operation under heavy load conditions. These transformers are extensively used in substations, manufacturing plants, and utility grids where stable and efficient voltage management is critical. Authoritative studies underline their applicability in renewable energy sectors, including photovoltaic power generation, due to their ability to handle voltage fluctuations efficiently. In aerospace, rail transit, and petrochemical industries, these transformers provide robust solutions under harsh environmental conditions, thus ensuring uninterrupted power supply and operational continuity.

Product After-Sales Service

- 24/7 customer support for technical issues

- Comprehensive warranty coverage

- Regular maintenance check-ups

- Spare part provisions and replacements

- On-site service available for critical cases

Product Transportation

- Secure packaging to prevent damage during transit

- Collaboration with reliable logistics partners for timely delivery

- Insurance coverage for high-value shipments

- Tracking available for real-time shipment updates

- Custom clearance handled by experienced personnel

Product Advantages

- High Reliability: Minimal maintenance required due to robust design

- Efficiency: Excellent thermal conductivity for efficient power handling

- Durability: Strong construction suited for diverse environmental conditions

- Cost-Effectiveness: Lower installation and operational costs

- Global Standards: Compliance with GB and IEC standards

Product FAQ

- Why choose an oil immersed self cooled transformer over others? As a supplier, we ensure these transformers offer superior efficiency and reliability with minimal maintenance compared to air-cooled variants.

- What maintenance is required for these transformers? Regular oil checks and inspections are recommended to ensure optimal performance and longevity, tasks our supplier team can assist with.

- Can these transformers be customized for specific needs? Absolutely, as a supplier, we provide customization options to suit specific voltage and capacity requirements.

- How does the oil in these transformers function? It acts as a coolant and insulator, enhancing efficiency and reliability, a key aspect managed by any reputed supplier of this technology.

- What is the expected lifespan of these transformers? With proper maintenance, these transformers can last several decades, showcasing durability synonymous with leading suppliers.

- Are these transformers environmentally friendly? Yes, these transformers are designed to minimize energy loss and are compliant with international environmental standards.

- What safety features are integrated into these transformers? Safety features include robust tank design, pressure relief devices, and high-quality insulation to prevent failures.

- Do you offer installation services? As a supplier, we provide comprehensive installation support, including on-site setup and commissioning.

- What is the lead time for delivery? Typically, our supplier network ensures a lead time of 6-8 weeks, subject to order specifications and quantity.

- How do these transformers handle overload conditions? Designed with high thermal capacity, these transformers efficiently manage overloads, ensuring consistent operation.

Product Hot Topics

- Efficiency Enhancements in Oil Immersed Self Cooled Transformers: Recent advancements have enabled suppliers to improve efficiency through better insulating materials and design optimizations, reducing energy losses significantly.

- Sustainability Initiatives by Leading Suppliers: The push towards renewable energy has driven suppliers to innovate and integrate more environmentally friendly practices in their transformer production processes.

- Impact of Global Standards on Transformer Manufacturing: Compliance with standards such as IEC/60076 has helped suppliers ensure quality and reliability, facilitating international trade and market expansion.

- Cost-Effective Solutions for Industrial Power Needs: Suppliers are now focusing on offering cost-effective transformer solutions without compromising on quality, making them more accessible to various industries.

- Transformers in Renewable Energy Applications: The application of oil immersed self cooled transformers in renewable energy sectors is a growing trend, with suppliers working on enhancing their compatibility.

- Innovations in Transformer Oil Technology: Suppliers are continuously researching and developing new insulating oils that offer better thermal performance and environmental safety.

- Global Supply Chain Challenges and Solutions: Suppliers are adapting to global supply chain disruptions by diversifying their logistics networks and leveraging technology for better forecasting and management.

- Adoption of Smart Technologies in Transformers: The integration of IoT and smart features in transformers is being explored by suppliers to offer better monitoring and maintenance capabilities.

- Enhancing Transformer Lifespan through Advanced Materials: Innovative materials used by suppliers are extending the lifespan and performance reliability of these crucial power components.

- Future Trends in Transformer Design and Efficiency: Suppliers anticipate continuing trends in compact designs and higher efficiency metrics, driven by demands for more sustainable electrical infrastructures.

Image Description