Reliable Supplier of 315 kVA Transformer Solutions

Product Main Parameters

| Parameter | Specification |

|---|---|

| Rated Capacity | 315 kVA |

| Voltage Level | 6-35 kV |

| Phase | Three |

| Cooling Type | Oil-Immersed |

Common Product Specifications

| Specification | Details |

|---|---|

| No-Load Losses | 480 W |

| Load Losses | 3650 W |

| No-Load Current | 1.4% |

| Short-Circuit Impedance | 4.0% |

Product Manufacturing Process

Our 315 kVA transformers are manufactured following strict quality guidelines. The process begins with selecting high-grade electrical steel and copper, ensuring minimal core and copper losses. Winding is performed with precision, utilizing automated machinery to ensure optimal alignment and tension. The core assembly is carefully insulated before the coil is mounted, followed by comprehensive testing to guarantee insulation integrity. Transformers undergo rigorous testing of electrical, mechanical, and thermal properties, aligning with international standards like IEC and ANSI. The final stage includes oil filling under vacuum to eliminate moisture, ensuring the transformer's reliability and longevity. In conclusion, our attention to detail and adherence to global standards ensure our 315 kVA transformers deliver exceptional performance and reliability, making us a leading supplier in the industry.

Product Application Scenarios

Our 315 kVA transformers are versatile, finding extensive applications across various sectors. In industrial settings, they supply power to heavy machinery, contributing to operational efficiency and productivity. In commercial buildings, they ensure stable power distribution across multiple floors, supporting lighting, HVAC systems, and office equipment. Renewable energy sectors benefit from their use in photovoltaic and wind systems, where they effectively step up or down the voltage to integrate with the grid. The reliable performance makes them ideal for critical infrastructure projects like rail transit and aerospace, where stable power is crucial. As a leading supplier, we ensure our transformers meet diverse requirements, making us a preferred choice in numerous application scenarios.

Product After-Sales Service

We offer comprehensive after-sales service, including installation support, regular maintenance checks, and technical assistance. Our team of experts ensures quick and efficient resolution of any issues, prioritizing customer satisfaction.

Product Transportation

Our transformers are packed securely and transported using specialized vehicles to prevent damage during transit. We coordinate with logistics providers to ensure timely delivery, adhering to international shipping standards.

Product Advantages

- High Efficiency: Our transformers offer excellent energy savings with low losses.

- Reliability: Robust design and manufacturing ensure long-term operational stability.

- Cost-Effective: Competitive pricing due to efficient production processes.

- Compliance: Meets international standards like IEC/60076 and GB regulations.

- Customizable: Tailored solutions to meet specific client needs.

Product FAQ

- What is the lifespan of a 315 kVA transformer from your company?

- Can the 315 kVA transformer handle overloads?

- What safety standards do your 315 kVA transformers meet?

- How to Optimize Transformer Efficiency?

Efficiency in transformers is crucial for reduced energy consumption and operational costs. Utilizing high-grade core materials, such as amorphous steel, minimizes core losses. Implementing advanced winding designs further reduces copper losses, enhancing overall efficiency. Regular maintenance, including inspection of insulation and electrical connections, is vital for sustained performance. As a reputable supplier, we ensure our 315 kVA transformers are designed with efficiency in mind, contributing to energy savings and cost-effectiveness for our clients.

- Trends in Power Transformer Technology

The power transformer industry continually evolves, with innovation focusing on improved efficiency and sustainability. Recent trends include the integration of smart technology, allowing real-time monitoring and predictive maintenance. The adoption of eco-friendly insulating materials reduces environmental impact, aligning with global sustainability goals. Energy-efficient designs minimize losses, providing enhanced performance. As a leading supplier, our 315 kVA transformers incorporate these advancements, ensuring cutting-edge solutions that meet current and future demands.

Our 315 kVA transformers typically have a lifespan of over 25 years with proper maintenance. Regular checks and adherence to operational guidelines can further extend their service life, ensuring reliable performance over time.

While designed for continuous operation at rated capacity, brief overloads are manageable. However, prolonged overloads should be avoided to prevent overheating and potential damage. Our after-sales service team can provide specific guidance based on your usage scenario.

Our transformers comply with international safety standards such as IEC/60076 and local GB regulations. They are designed with safety in mind, featuring proper insulation, grounding, and protective measures to ensure safe operation.

Product Hot Topics

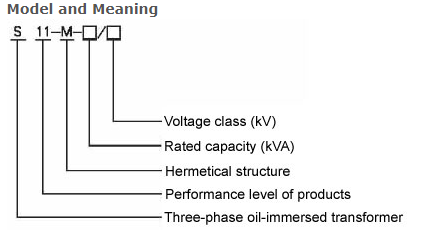

Image Description