Daily Maintenance: Oil Levels and Temperature

Monitoring Oil Levels

For optimal performance of oil-immersed transformers, daily monitoring of oil levels is essential. The Magnetic Oil Gauge (MOG) is a critical tool used to ensure oil levels are within specified parameters, typically indicated in liters or gallons. It's important to check these levels at a stable transformer temperature, generally around 25°C (77°F), to avoid misleading measurements caused by thermal expansion.

Temperature Checks

The operational stability of oil immersed self cooled transformers heavily relies on maintaining appropriate temperature levels. Monitoring ambient, winding, and oil temperatures using attached thermometers or thermocouples ensures that these remain within the operational limits, typically between 10°C to 90°C (50°F to 194°F). Exceeding these temperatures could indicate underlying issues requiring immediate attention.

Visual Inspection Tasks

Identifying Leaks and Damage

Daily visual inspections are crucial in catching signs of oil leaks or physical damage early. Inspect all gaskets, seals, and flanges for wet spots or oil stains that might indicate leaks. This practice helps avoid larger issues that might impair transformer performance or cause costly failures.

Silica Gel Condition

The breather system uses silica gel to maintain a dry internal environment by absorbing moisture. Checking the color of the silica gel daily, typically indicating saturation when blue changes to pink, allows for timely replacement. This is vital for preventing moisture ingress that can deteriorate insulating properties.

Weekly/Monthly Maintenance: Addressing Oil Leakage

Scheduled Inspections for Leak Prevention

Maintaining an inspection schedule on a weekly or monthly basis helps ensure that any oil leakage is promptly addressed. It is recommended to inspect joints, fittings, and seals, tightening bolts or replacing seals as necessary. This is especially critical in regions where humidity levels are high, often increasing the risk of leaks.

Checking for Signs of Corrosion

Corrosion can lead to structural damage and impair functionality. Inspect transformer surfaces for rust or paint damage that could allow moisture penetration. Applying anti-corrosion paint or sealant as needed, especially in coastal or industrial environments, plays a crucial part in extending the transformer's lifespan.

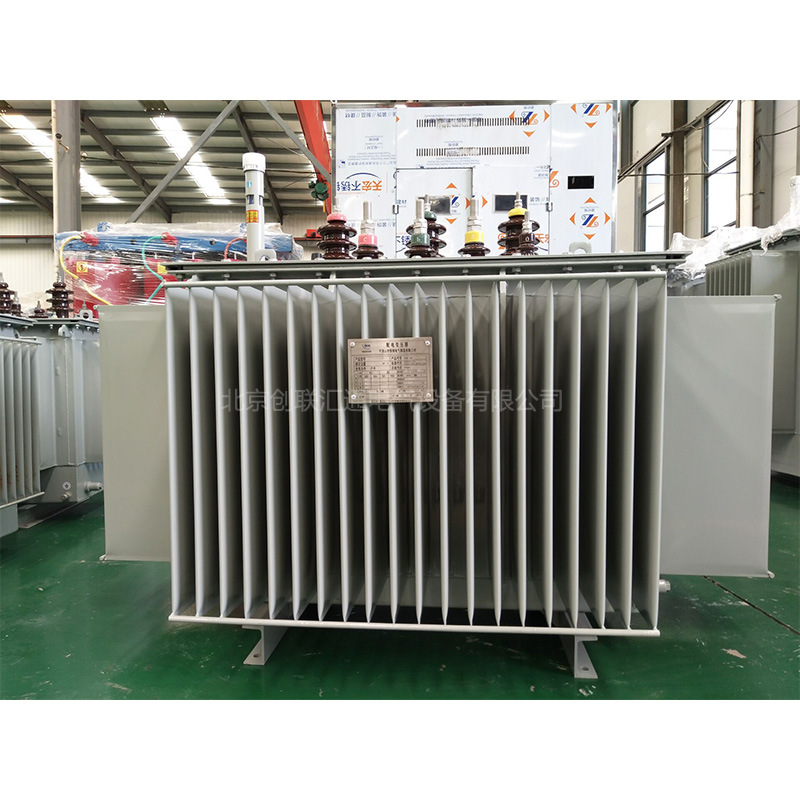

Exterior Maintenance: Preventing Corrosion and Damage

Regular Cleaning Practices

Keeping the transformer's exterior clean prevents the accumulation of dust and debris, which could exacerbate corrosion. A gentle wash with water and non-corrosive detergents is recommended, avoiding high-pressure sprays that might damage sensitive parts.

Weatherproofing Measures

Ensure all weatherproof seals are intact, especially around marshaling boxes. This is pivotal in preventing moisture ingress, which can lead to internal component failures. Inspect these seals at least once a month or after significant weather events, such as heavy rain or storms.

Dielectric Strength and Insulation Resistance Testing

Checking Dielectric Oil Strength

Testing the dielectric strength of transformer oil is integral in maintaining its insulating properties. This can be determined using a dielectric tester, whereby the breakdown voltage is measured; satisfactory performance is typically indicated by a voltage of 30 kV or higher. Routine checks can prevent arcing and short circuits.

Insulation Resistance Verification

Insulation resistance testing is conducted using a Megger insulation tester to assess cable and winding insulation conditions. A resistance value of 100 megaohms or more is generally considered acceptable. Regular testing helps in identifying potential insulation failures before they result in irreversible damage.

Cooling System and Pressure Relief Device Checks

Cooling System Efficiency

Ensuring the transformer cooling system operates efficiently is essential for dissipating heat generated during operation. This involves checking radiator fans, pumps, and oil flow rates, which should fall within system specifications, usually between 0.1 to 0.5 cubic meters per second for oil flow.

Functionality of Pressure Relief Devices

Pressure relief devices are designed to prevent the buildup and release of excess pressure that could otherwise lead to catastrophic failures. A functional integrity check, typically performed monthly, involves visual and mechanical inspections to ensure these devices are operational and free from obstructions.

Annual Maintenance: Detailed Internal Inspection

Comprehensive Component Inspections

Annual maintenance necessitates a thorough internal inspection, often involving disassembly of key components by qualified technicians. This includes examining core and coil assemblies for structural integrity and signs of thermal or electrical wear.

Functionality of Temperature Indicators

The proper operation of temperature indicators and off-circuit selector switches ensures accurate monitoring and operational adjustments. If readings deviate beyond expected norms, replacing these indicators can prevent erroneous data that could lead to inefficiencies or system failure.

Weatherproof Seals and Grounding Device Inspection

Inspecting and Maintaining Weatherproof Seals

Weatherproof seals play a critical role in protecting internal components from environmental factors. These seals must be inspected annually for cracks or weaknesses and replaced when necessary to maintain proper environmental isolation.

Grounding Device Health

Proper grounding is crucial for safety and the prevention of electrical shock hazards. Annual inspections ensure grounding connections are secure and free of corrosion, ensuring that fault currents are safely dissipated into the ground.

DC Resistance Testing

Ensuring Electrical Integrity

DC resistance testing helps ascertain the continuity and integrity of the winding resistance. Discrepancies in resistance readings might indicate issues such as partial short circuits, loose connections, or conductor damage, requiring immediate attention to maintain transformer performance.

Testing Parameters and Results Analysis

Typical DC resistance values vary with transformer size and configuration, but any sudden deviation from baseline readings should be carefully analyzed. A variation of more than 5% from the expected resistance values can be a preliminary indicator of winding problems.

General Maintenance Practices and Safety Protocols

Ensuring Cleanliness and Environmental Control

Regular cleaning improves transformer efficiency and longevity. Maintaining a clean and dry operational environment minimizes the risk of external contaminants impacting performance. In wholesale transformer setups, especially those sourced from suppliers in China, consistent maintenance practices are critical to ensure products meet international standards.

Documenting Maintenance Activities

Maintaining meticulous records of all inspections, findings, and corrective actions is fundamental. This documentation facilitates trend analysis, helping to anticipate potential failures and plan targeted interventions, enhancing the reliability of power supply systems.

Adhering to Safety Measures

- Always disconnect the transformer from the power supply before performing maintenance.

- Ensure all personnel are equipped with appropriate personal protective equipment (PPE).

- Follow standardized safety protocols to mitigate risk during maintenance procedures.

Global Power Equipment Provide Solutions

Global Power Equipment offers comprehensive solutions for transformer maintenance, enhancing operational reliability and extending service life. By providing tailored maintenance plans and high-quality components, our solutions help mitigate risks associated with electrical equipment failure. With a strong supply chain network, including verified suppliers from China, Global Power Equipment ensures timely access to essential maintenance parts and services. By leveraging global resources, we support the sustainable and efficient operation of power systems worldwide.