23

Mar

Introduction to Transformers

Transformers are indispensable components within electrical power distribution systems, primarily facilitating the efficient and safe transfer of electrical energy from power generation stations to end-users, including homes and businesses. These devices act as crucial intermediaries between high-voltage transmission lines and the low-voltage distribution lines that deliver power to our everyday appliances. In this article, we delve into the distinct differences between two common types of transformers: pad-mounted and ground-mounted transformers. Understanding these differences is essential for making informed decisions when selecting transformers for specific applications.

● Types of Transformers

Transformers come in various designs and configurations, each tailored to specific operational requirements and environmental conditions. The two primary types under discussion—pad-mounted transformers and ground-mounted transformers—are integral to diverse distribution networks. While they share the common purpose of stepping down voltage levels for distribution, their design and application contexts vary significantly.

● Role of Transformers in Electrical Distribution

Transformers play a pivotal role in the electrical distribution framework. They enable the conversion of high-voltage electricity generated at power plants into lower voltages suitable for residential and commercial use. By efficiently handling voltage transformations, transformers minimize power loss during transmission, ensuring a stable and reliable electricity supply.

Understanding Pad-Mounted Transformers

● Definition and Characteristics

Pad-mounted transformers are self-contained units designed to operate at ground level. Encased in a metal enclosure, they are typically installed on a concrete pad, providing easy access for maintenance and operation. These transformers are often found in urban and suburban environments where overhead lines are impractical or undesirable.

● Typical Applications and Uses

Pad-mounted transformers are widely used in settings that demand aesthetic considerations, such as residential neighborhoods and commercial complexes. Their design eliminates the need for unsightly utility poles and overhead wires, contributing to a more visually appealing environment. Additionally, they are ideal for areas where underground power distribution systems are prevalent, such as densely populated cities.

Features of Pad-Mounted Transformers

● Protective Enclosures and Safety Features

One of the defining features of pad-mounted transformers is their protective enclosure, which houses the transformer apparatus and associated components. This design not only offers protection against environmental elements but also enhances safety by preventing unauthorized access and minimizing the risk of accidental contact. These enclosures are often equipped with lockable doors and are designed to withstand harsh weather conditions.

● Switching Options and Accessibility

Pad-mounted transformers typically include switching options that allow for easy isolation of the transformer from the power grid for maintenance purposes. Their ground-level installation makes them easily accessible for inspection and servicing, reducing the time and effort required for routine maintenance operations. This accessibility is particularly advantageous in urban settings, where space constraints may otherwise complicate maintenance activities.

Ground-Mounted Transformers Overview

● Definition and Characteristics

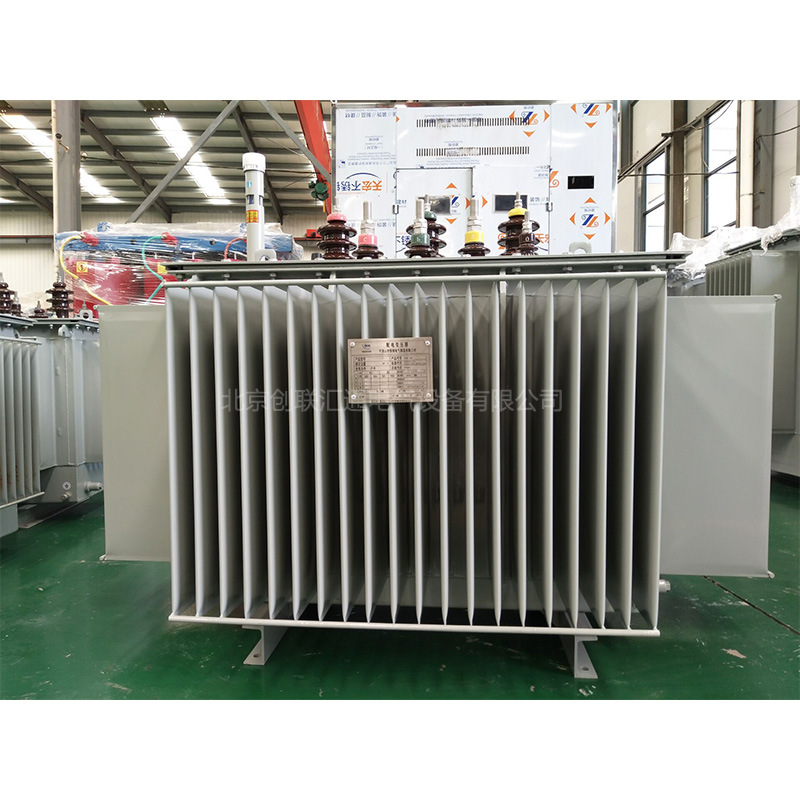

Ground-mounted transformers, although similar in some aspects to pad-mounted transformers, are distinct in their installation and design. These transformers are also situated at ground level but may lack the fully enclosed design characteristic of pad-mounted transformers. Ground-mounted transformers are often used in industrial settings where space is not a primary concern, and robust performance is prioritized.

● Differences from Pad-Mounted Transformers

The primary difference between pad-mounted and ground-mounted transformers lies in their enclosure and intended applications. While pad-mounted transformers are enclosed and designed for environments where aesthetics and public safety are essential, ground-mounted transformers may be more exposed and suited to industrial or less populated areas where these concerns are of lesser importance.

Design and Construction Differences

● Physical Differences: Size and Shape

The physical design of pad-mounted transformers tends to be more compact and streamlined compared to ground-mounted transformers. Pad-mounted units are engineered to occupy minimal space, making them suitable for areas where space efficiency is critical. In contrast, ground-mounted transformers may be larger and more robust, reflecting their use in industrial applications where size is secondary to performance.

● Installation Requirements and Settings

The installation of pad-mounted transformers typically involves placing the unit on a concrete pad and connecting it to the distribution network through underground cables. This setup is conducive to urban and suburban settings, where overhead lines are impractical. Ground-mounted transformers, on the other hand, may be installed directly on the ground without the need for a dedicated pad, making them more adaptable to varied terrain and industrial environments.

Applications of Ground-Mounted Transformers

● Common Uses in Industrial Settings

Ground-mounted transformers are commonly employed in industrial facilities, construction sites, and other settings where heavy-duty electrical supply is necessary. Their design is optimized for high-load applications, ensuring reliable performance even under demanding conditions. These transformers are integral to operations where consistent voltage transformation is crucial to maintaining production efficiency and equipment safety.

● Benefits of Ground-Mounted Transformers

The primary advantage of ground-mounted transformers is their ability to handle higher power capacities compared to pad-mounted transformers. This capability makes them ideal for industrial applications where power demands are substantial. Additionally, their comparatively straightforward design and installation process can lead to cost savings in both initial setup and long-term maintenance.

Comparison of Efficiency and Maintenance

● Efficiency Considerations for Both Types

Both pad-mounted and ground-mounted transformers are engineered to deliver optimal performance in their respective environments. However, efficiency considerations may vary depending on the application and specific operational requirements. Pad-mounted transformers, with their compact design, are often more efficient in settings where space and noise reduction are priorities. Conversely, ground-mounted transformers excel in industrial contexts where power capacity and durability are paramount.

● Maintenance Needs and Challenges

Maintenance requirements for pad-mounted and ground-mounted transformers can differ based on their design and installation environment. Pad-mounted transformers, with their enclosed design, typically demand less frequent maintenance. However, their complexity may entail more specialized skills for repairs. Ground-mounted transformers are generally easier to service due to their accessibility and simpler construction, though they may require more regular attention due to exposure to environmental elements.

Safety and Environmental Considerations

● Safety Protocols for Installation and Operation

Both pad-mounted and ground-mounted transformers necessitate adherence to rigorous safety protocols during installation and operation to ensure the protection of personnel and equipment. Pad-mounted transformers, with their enclosed design, inherently offer enhanced safety features such as lockable doors and barriers to prevent unauthorized access. Ground-mounted transformers, while requiring additional safety measures, can be installed with protective barriers or fencing to mitigate risks.

● Environmental Impact and Noise Levels

Pad-mounted transformers, being enclosed, generally have a lower environmental impact in terms of noise pollution. Their design helps suppress operational noise, making them suitable for residential areas. Ground-mounted transformers, on the other hand, may produce more noise due to their exposed configuration, necessitating careful consideration of their placement in noise-sensitive environments.

Cost Implications for Both Transformer Types

● Initial Installation Costs

The cost implications of installing pad-mounted versus ground-mounted transformers can vary based on several factors, including location, capacity, and specific requirements of the installation site. Pad-mounted transformers, with their need for concrete pads and additional safety features, may involve higher initial installation costs. Ground-mounted transformers, by virtue of their simpler installation process, may offer cost advantages in certain contexts.

● Long-Term Operational Costs

While pad-mounted transformers may incur higher upfront costs, their efficient design and reduced maintenance needs can lead to lower long-term operational expenses. Ground-mounted transformers, with potentially higher maintenance requirements, may incur additional costs over their operational lifespan. However, their robust performance in high-demand applications can offset these expenses by ensuring stable and reliable power supply.

Conclusion and Future Trends

● Evolving Technology in Transformer Design

The landscape of transformer technology is continually evolving, with advancements focusing on increasing efficiency, reducing environmental impact, and enhancing safety features. Innovations in materials and design are paving the way for transformers that are more resilient and adaptable to diverse application environments.

● Future Developments in Energy Distribution

As the global energy sector transitions towards more sustainable and renewable sources, the role of transformers is set to expand and adapt. Future developments are likely to emphasize integration with renewable energy systems, improved energy efficiency, and enhanced connectivity for smart grid applications.

Global Power Equipment: A Leader in Transformer Solutions

Global Power Equipment (Xuzhou) Co.,Ltd. is a leading enterprise in the production and development of power transformers, including the renowned S11, S13, and other series. The company's extensive range of products serves various industries, from thermal and hydropower to rail transit and aerospace. Established in 2013, Global Power Equipment combines advanced technology with a commitment to quality and sustainability, providing reliable solutions across Europe, South America, Africa, and Asia. With a focus on innovation and customer satisfaction, Global Power Equipment stands out as a trusted partner in global energy solutions.