19

May

Introduction

Transformers are critical components in the transmission and distribution of electrical energy, enabling voltage levels to be adjusted for efficient power distribution. Among the numerous types of transformers available, dry-type and oil-type transformers stand out due to their distinct cooling and insulating mechanisms. As energy demands continue to grow, understanding these differences becomes crucial for decision-makers in the energy sector.

Cooling Media: Dry vs. Oil Transformers

● Air Cooling in Dry-Type Transformers

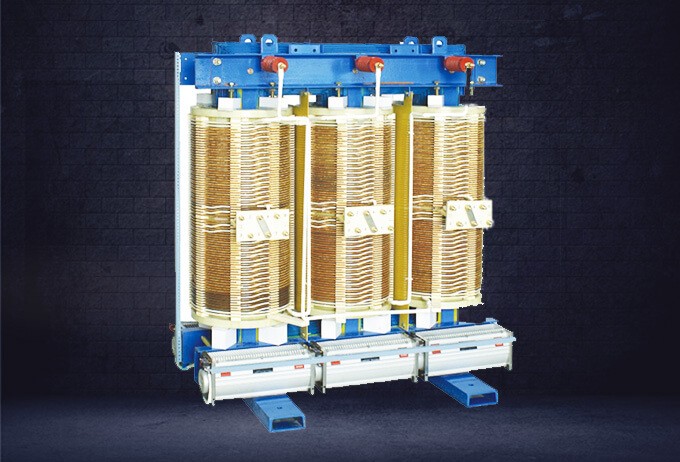

Dry-type transformers utilize air as their primary cooling medium. Unlike oil-type transformers, which rely on liquid cooling, these transformers depend on air to dissipate heat generated during operation. The absence of oil reduces the risk of fire hazards, making them a safer choice in certain environments. Wholesale dry-type transformers and China dry-type transformers are gaining popularity for their safety profile and ease of installation.

● Oil Cooling in Oil-Type Transformers

Oil-type transformers, on the other hand, utilize mineral oil for cooling and insulation purposes. The oil not only dissipates heat but also acts as an insulating medium between the windings and the core. This cooling mechanism allows for efficient heat transfer, making oil-type transformers a preferred choice in applications where compactness and efficiency are essential.

Insulation Mechanisms and Materials

● Insulation in Dry-Type Transformers

Dry-type transformers rely on air gaps and solid insulating materials, such as polyester varnish or epoxy, to provide the necessary electrical insulation. These materials enhance the transformer’s ability to withstand high voltage levels without the risk of breakdown. Dry-type transformer manufacturers and suppliers emphasize the importance of high-quality insulation materials to ensure longevity and reliability.

● How Mineral Oil Insulates in Oil-Type Transformers

In oil-type transformers, the mineral oil serves a dual purpose: it cools the transformer and provides electrical insulation. The oil forms a dielectric layer that prevents electrical arcs and maintains the integrity of the windings. Oil-type transformers’ efficiency in insulation and cooling makes them a staple in high-capacity applications, such as substations and industrial facilities.

Advantages of Dry-Type Transformers

● Safety in Fire-Prone Areas

The absence of flammable oil in dry-type transformers makes them inherently safer for installation in locations where fire hazards are a concern. This characteristic is particularly appealing for indoor applications and urban environments, where safety is paramount.

● Low Maintenance and Environmental Benefits

Dry-type transformers require minimal maintenance compared to their oil-filled counterparts. The lack of oil eliminates concerns about oil degradation, leaks, and disposal, making them an environmentally friendly option. This aspect aligns with the increasing global demand for sustainable solutions, further boosting the market for dry-type transformer factories and suppliers.

Disadvantages of Dry-Type Transformers

● Cost Implications

Despite their advantages, dry-type transformers generally come with a higher price tag than oil-type transformers. The cost is attributed to the materials used and the design complexities involved in manufacturing high-performance dry-type units. This can be a limiting factor for projects with stringent budget constraints.

● Efficiency and Noise Concerns

Dry-type transformers are known to be less efficient in heat dissipation compared to oil-type transformers. This inefficiency may lead to larger, less compact units, which can be a drawback in space-constrained environments. Additionally, dry-type transformers may produce higher noise levels, which can be a consideration for sensitive installations.

Advantages of Oil-Type Transformers

● Heat Dissipation and Compactness

Oil-type transformers excel in heat dissipation, allowing for more compact designs than their dry-type counterparts. This advantage makes them suitable for installations where space is limited, without compromising on performance. Their efficient cooling also contributes to lower operational costs over time.

● Cost Efficiency and Noise Reduction

Generally, oil-type transformers are less expensive to manufacture, contributing to their widespread use in cost-sensitive applications. Additionally, they tend to operate more quietly than dry-type transformers, which can be a significant advantage in noise-sensitive environments, such as residential areas.

Disadvantages of Oil-Type Transformers

● Fire and Environmental Risks

The use of flammable oil in oil-type transformers presents inherent fire risks, necessitating careful consideration of safety protocols and installation standards. Furthermore, environmental concerns arise from the potential for oil spills and the complexities involved in oil disposal, prompting a need for specialized infrastructure and containment measures.

● Maintenance Requirements and Infrastructure Needs

Oil-type transformers require regular maintenance, including oil testing, filtering, and potential replacement, to ensure optimal performance and longevity. This maintenance demand can lead to higher operational costs and necessitates infrastructure, such as oil containment pits, to prevent environmental contamination.

Application Scenarios for Dry-Type Transformers

● Suitable Environments and Industries

Dry-type transformers are ideally suited for environments that prioritize safety and environmental considerations, such as commercial buildings, hospitals, and educational institutions. Their robust design and low maintenance make them a reliable choice for critical applications that demand high uptime and reliability.

● Considerations for Installation Indoors

The flexibility and safety profile of dry-type transformers allow for their installation in various indoor settings without the need for additional containment measures. This versatility supports their use in urban locations where space may be limited, enhancing their appeal to dry-type transformer manufacturers and suppliers worldwide.

Application Scenarios for Oil-Type Transformers

● Industrial Uses and Outdoor Settings

Oil-type transformers' efficient cooling and compact design make them ideal for industrial applications and outdoor settings, such as substations and power plants. Their ability to handle high capacities and demanding environments underscores their importance in the energy sector.

● Infrastructure and Safety Measures

The installation of oil-type transformers requires careful planning and adherence to safety standards. Specialized infrastructure, such as oil containment pits and fire protection systems, is necessary to mitigate risks and ensure safe operation. These considerations are crucial for oil-type transformer manufacturers and users alike.

Conclusion and Selection Criteria

When choosing between dry-type and oil-type transformers, decision-makers must weigh factors such as safety, cost, efficiency, and environmental impact. Both types offer unique advantages and disadvantages that must be aligned with the specific needs of the application. As technology continues to evolve, innovations in transformer design and materials promise to enhance performance and sustainability, offering new opportunities for the energy industry.

Company Introduction: Global Power Equipment

Global Power Equipment (Xuzhou) Co., Ltd. is a leading group enterprise specializing in the production, research, and development of power transformers, including S11, S13, S20, S22, and SCB series. Founded in 2013 and located in Jiangsu Xuzhou Economic Development Zone, the company boasts a robust R&D team and state-of-the-art manufacturing facilities. With a focus on innovation and quality, Global Power Equipment serves a global clientele, covering markets across Europe, South America, Africa, and Southeast Asia. Their commitment to excellence and sustainable development underscores their reputation as a trusted leader in the power transformer industry.