13

Mar

Introduction to PCB Mount Transformers

PCB mount transformers are essential components in modern electronic devices, serving as a critical link in power conversion systems. These transformers are designed to be mounted directly on a printed circuit board (PCB), offering a compact and efficient solution for power management. Understanding their functionality and application is crucial for engineers and designers working in the electronics field.

● Definition and Basic Concept

A PCB mount transformer is a type of transformer specifically designed to be integrated onto a PCB. It functions by transferring electrical energy between two circuits through electromagnetic induction, offering electrical isolation and voltage transformation capabilities. This isolation is vital to protect sensitive electronic components from power surges and electrical noise.

● Importance in Electronic Devices

PCB mount transformers are integral to numerous applications, from small consumer electronics to large industrial systems. They ensure efficient power conversion and distribution, contributing to the reliability and functionality of the devices. Their compact size and ability to provide electrical isolation make them indispensable in modern electronics design.

Working Principle of PCB Mount Transformers

To truly grasp the significance of PCB mount transformers, one must understand their fundamental working principle, which is rooted in electromagnetic induction.

● Electromagnetic Induction Explained

At the core of a PCB mount transformer's operation is electromagnetic induction. When alternating current flows through the primary winding, it creates a magnetic field that induces a voltage in the secondary winding. This process enables the transfer of electrical energy without a direct connection, providing both isolation and transformation functions.

● Role of Primary and Secondary Windings

The primary winding receives the input voltage, while the secondary winding delivers the transformed output voltage. The ratio of turns between these windings determines the voltage transformation level. This relationship is crucial for designing transformers that meet specific application requirements, such as stepping up or stepping down voltage levels.

Construction and Components of PCB Transformers

The construction of a PCB mount transformer significantly influences its performance and reliability in electrical circuits.

● Materials Used in Core and Windings

The core typically consists of magnetic materials like ferrite or laminated silicon steel, chosen for their high magnetic permeability. The windings are made from copper or aluminum, providing efficient electrical conductivity. The choice of these materials impacts the transformer's efficiency, size, and cost.

● Design Considerations for Efficiency

Effective design of PCB mount transformers involves optimizing their core geometry, winding configuration, and insulation to minimize losses and maximize efficiency. Factors such as core saturation, copper losses, and dielectric breakdown are critical considerations during the design process.

Types of PCB Mount Transformers

PCB mount transformers come in various types, each suited to different applications and design requirements.

● Step-up vs. Step-down Transformers

Step-up transformers increase the output voltage relative to the input, while step-down transformers decrease it. The application determines the choice between these two types, with each serving distinct roles in power conversion systems.

● Isolation and Autotransformers

Isolation transformers provide electrical separation between input and output circuits, enhancing safety and noise suppression. Autotransformers, on the other hand, use a single winding for both input and output, offering a more compact and cost-effective solution for voltage transformation.

Applications of PCB Transformers in Electronics

The versatility of PCB mount transformers allows them to be employed across various sectors in electronics.

● Usage in Power Supply Circuits

In power supply circuits, PCB mount transformers are pivotal in converting AC power from the mains to DC power used by electronic devices. They facilitate voltage adjustments to match the specific requirements of different components.

● Importance in Signal Isolation

Signal isolation is crucial in preventing ground loops and reducing electromagnetic interference in sensitive equipment. PCB mount transformers serve as isolators, ensuring clean and reliable signal transmission in complex electronic systems.

Advantages of Using PCB Transformers

The adoption of PCB mount transformers in electronic design offers multiple advantages that enhance both functionality and production efficiency.

● Compact Size for Space Efficiency

One of the primary benefits of PCB mount transformers is their compact size, which allows for efficient use of space on the PCB. This is crucial in modern electronics, where miniaturization is often a key goal.

● Cost-effectiveness in Manufacturing

PCB mount transformers are generally more cost-effective to manufacture and integrate compared to traditional transformers. Their standardized design and materials contribute to lower production costs, which is advantageous for high-volume manufacturing.

Limitations and Challenges of PCB Transformers

Despite their benefits, PCB mount transformers present certain limitations and challenges that designers must address.

● Thermal Management and Cooling Needs

Operating under high power conditions can lead to significant heat generation. PCB mount transformers require effective thermal management techniques, such as heat sinks or thermal vias, to dissipate heat and maintain performance.

● Limitations in Power Handling Capacity

While suitable for a broad range of applications, PCB mount transformers may not handle very high power levels as efficiently as larger, standalone transformers. Designers need to balance power requirements with the transformer's capabilities.

Design Considerations for PCB Transformers

Designing PCB mount transformers involves careful consideration of various factors to ensure optimal performance and reliability.

● Core Material Selection Criteria

Selecting the right core material is essential for maximizing magnetic efficiency and minimizing losses. The choice depends on the frequency of operation, power levels, and environmental conditions.

● PCB Layout and Space Constraints

Incorporating PCB mount transformers into a PCB layout requires strategic planning to accommodate space constraints and ensure compatibility with other components. Designers must optimize trace routing and component placement to achieve efficient power distribution.

Installation and Mounting Techniques

Proper installation and mounting of PCB mount transformers are crucial for maintaining electrical integrity and mechanical stability.

● Soldering and Placement Guidelines

Soldering techniques must ensure secure electrical connections and mechanical stability. Proper alignment and placement on the PCB prevent stress on solder joints and reduce the risk of failure during operation.

● Ensuring Electrical Safety and Reliability

Ensuring electrical safety involves adhering to industry standards and guidelines, such as maintaining adequate creepage and clearance distances. Reliable installations minimize the risk of electrical hazards and enhance the overall durability of the device.

Future Trends in PCB Transformer Technology

The field of PCB mount transformers is continually evolving, driven by advancements in materials and design techniques.

● Innovations in Materials and Design

Emerging materials with higher magnetic permeability and thermal conductivity are being developed to enhance transformer performance. Advanced design methodologies, such as computer-aided optimization, are also contributing to more efficient and compact transformer solutions.

● Impact of Technological Advancements in Electronics

As electronics technology advances, the demand for more efficient and capable PCB mount transformers will grow. Innovations in power electronics, renewable energy, and automation are likely to shape the future landscape of transformer technology.

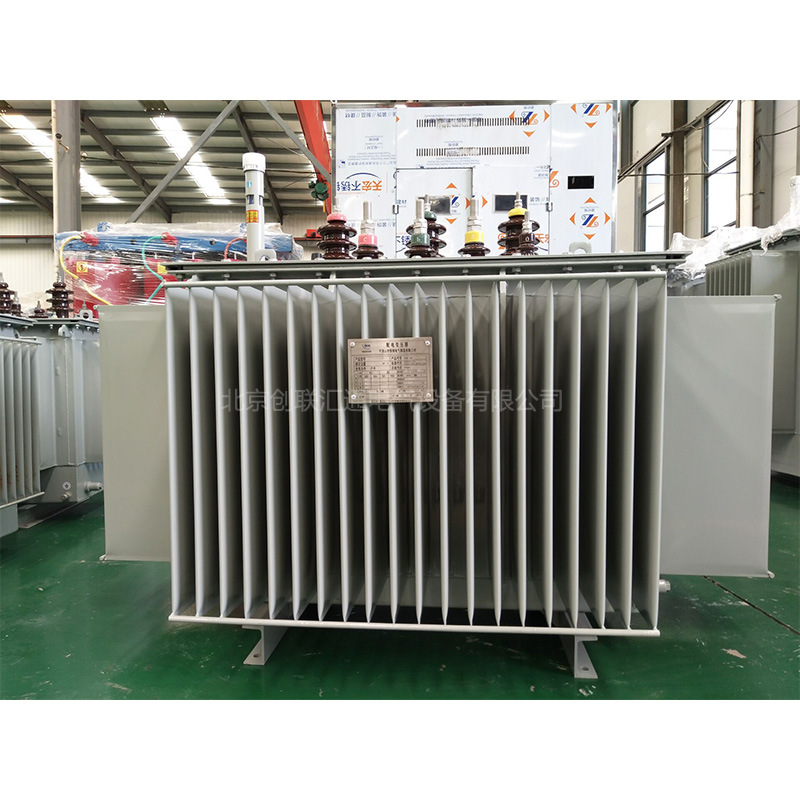

About Global Power Equipment

Global Power Equipment (Xuzhou) Co., Ltd. is a leader in the development and production of various power transformers, including S11, S13, S20, and SCB series. Established in 2013 following the restructuring of a state-owned enterprise, the company boasts a robust R&D and production team. With a focus on innovation, Global Power Equipment offers advanced, reliable products used in diverse fields such as thermal power, hydropower, and photovoltaic energy. The company is committed to quality and sustainable development, serving a global market with integrity and excellence.