Understanding Amorphous Alloy Transformers

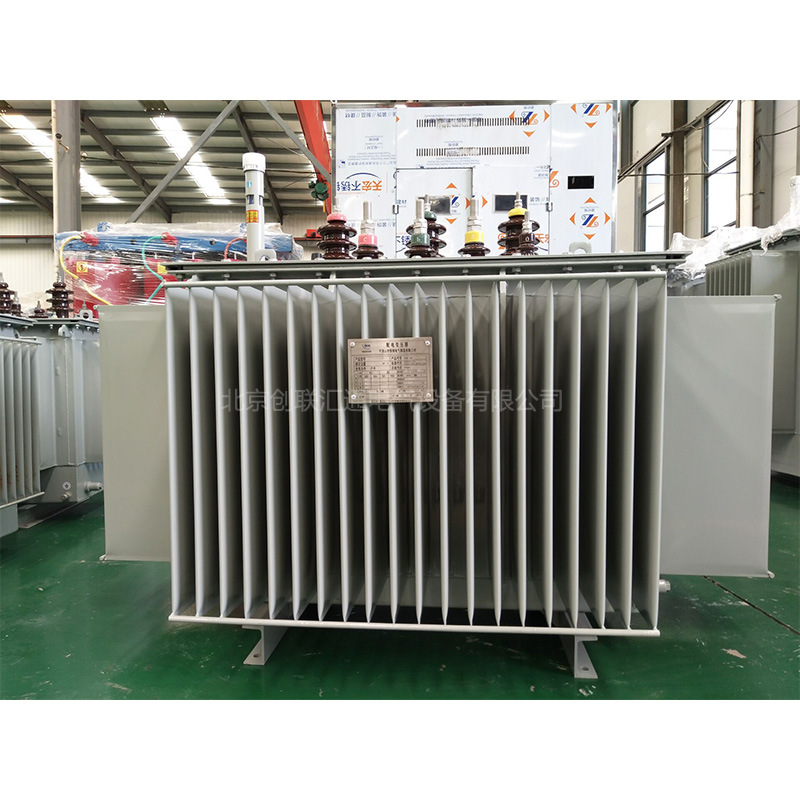

Amorphous alloy transformers, also known as amorphous core transformers, have emerged as a vital component in modern electrical distribution systems. These transformers leverage the unique properties of amorphous metals to achieve higher energy efficiency compared to traditional silicon steel transformers. The core material's structure minimizes core losses, making these transformers an excellent choice for energy-conscious industries. When sourcing these transformers on a wholesale basis, particularly from suppliers in China, it is crucial to understand their design, production, and applications.

Importance of Supplier Selection

Wholesale Partnerships and Business Growth

Choosing the right supplier is crucial for businesses aiming to establish successful wholesale operations. This decision significantly impacts your supply chain efficiency, cost management, and long-term growth prospects. Partnering with a reputable supplier in China can offer competitive advantages such as cost-effective manufacturing and access to a wide array of transformer specifications.

Assessing Product Quality Standards

Material Integrity and Performance Metrics

The quality of an oil immersed amorphous alloy transformer primarily depends on the material integrity and performance metrics, such as core loss, permeability, and electrical resistance. When selecting a supplier, ensure they adhere to international quality standards like IEC or ASTM. In China, many suppliers offer customizable solutions that cater to specific industry requirements while maintaining high quality.

Evaluating Production Capacity

Current and Future Demand Management

The production capacity of your supplier will directly affect your ability to meet your current and future demand. Suppliers with scalable production capabilities are likely to support business growth and accommodate increasing wholesale orders without compromising lead times. In China, large-scale suppliers might offer advanced production facilities that can handle high-volume demands efficiently.

Considering Engineering Support

Onsite Engineering Consultation

Comprehensive engineering support is an essential service that suppliers should offer, ensuring that transformers meet specific technical requirements. Local engineering teams provide real-time consultation and problem-solving capabilities. This support is especially critical when dealing with custom transformer orders that require precise specifications and performance assurances.

Outsourced Engineering Assistance

Communication and Efficiency Challenges

While some suppliers might outsource their engineering services, this can introduce challenges in terms of communication and efficiency. Misunderstandings can lead to product mismatches or delays, impacting project timelines. Ensure that your supplier has a robust mechanism for coordination between outsourced engineering teams and in-house production departments.

Financial Stability of Suppliers

Long-term Reliability and Partnerships

A supplier's financial health is indicative of their reliability and capability to manage ongoing operations without disruption. A financially sound supplier can maintain consistent production, invest in technological advancements, and offer stable pricing for wholesale clients. For businesses relying on continuous supply from China, this stability is a key factor in choosing a supplier.

Cost vs. Value Analysis

Balancing Price and Quality

While low cost is a tempting factor when choosing a supplier, it should not come at the expense of quality. Conduct a thorough cost vs. value analysis to ensure that the pricing aligns with the quality standards you expect. Suppliers in China often offer competitive pricing due to economies of scale, but verifying the quality through certifications and customer reviews is essential.

Analyzing Supplier Experience and Reputation

Industry Track Record and Client Feedback

The experience and reputation of a supplier can provide insight into their operational efficiency and reliability. A supplier with an extensive track record in the amorphous alloy transformer industry is likely to have refined their processes and supply chain management. Check for client feedback and industry reviews to gauge their reputation and customer satisfaction levels.

Technological Capabilities and Innovation

Advanced Manufacturing Techniques

Suppliers that invest in technological innovation and advanced manufacturing techniques are better positioned to offer transformers with superior performance characteristics. This includes using state-of-the-art equipment for precision manufacturing and quality control. In China, suppliers that focus on R&D can develop products optimized for specific applications and emerging industry needs.

Strategic Geographic Location and Logistics

Supply Chain Optimization and Delivery Times

The geographic location of a supplier plays a crucial role in supply chain management and logistics. Suppliers located in regions with efficient shipping and transport infrastructure can ensure faster lead times and reliable delivery schedules. This aspect is particularly important when sourcing from China, where logistical efficiency can greatly impact wholesale operations.

Global Power Equipment Provide Solutions

For businesses seeking reliable amorphous alloy transformer suppliers, focusing on quality, capacity, support, and technological expertise is paramount. A comprehensive evaluation of potential suppliers in China can lead to partnerships that drive business growth and efficiency. By prioritizing these factors, companies can ensure a steady supply and exceptional product performance. Partnering with a well-established supplier can streamline operations, reduce costs, and enhance overall competitiveness in the global market.