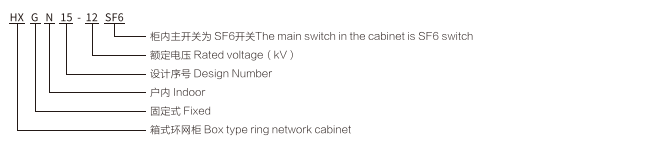

Manufacturer of Overhead Distribution Transformer HXGN

Product Main Parameters

| Parameter | Value |

|---|---|

| Rated Voltage | 3, 6, 10KV |

| Frequency | 50HZ |

| Altitude | Up to 2000m |

| Temperature Range | -25℃ to 40℃ |

Common Product Specifications

| Specification | Detail |

|---|---|

| Material | Silicon steel core, Copper/aluminum windings |

| Protection Level | IP3x |

| Main Switch | SF6 switch |

Product Manufacturing Process

The manufacturing process of the HXGN overhead distribution transformer involves several key stages. Initial development starts with CAD design and simulation to ensure that the transformer meets required specifications. High-quality materials, such as silicon steel and conductive metal windings, are selected for optimal efficiency. Core assembly involves precise lamination and binding to minimize energy loss. The windings are manually or machine-wound, ensuring uniformity and balance. Each unit is vacuum impregnated with high-performance insulating fluid. Once the transformer is assembled, it undergoes rigorous testing for performance, safety, and durability. These include impulse tests, open-circuit tests, and short-circuit tests that confirm compliance with international standards. Finally, the product is environmentally packaged and readied for distribution. This comprehensive process guarantees a product that combines reliability, efficiency, and longevity.

Product Application Scenarios

The HXGN overhead distribution transformer is versatile and can be employed in various sectors due to its robust design. Frequently used in urban and rural electrical grids, it allows for seamless voltage conversion from medium to low voltage levels, facilitating power delivery to residential, commercial, and industrial clients. Its application extends to remote areas where overhead systems are more feasible than underground installations. Additionally, it's ideal for infrastructural projects like railways and subways where space constraints and operational reliability are critical. The transformer's adaptability allows it to support dynamic load fluctuations, making it a staple in disaster recovery scenarios and temporary power setups.

Product After-Sales Service

Our manufacturer provides a comprehensive after-sales service package, including a two-year warranty, regular maintenance checks, and a dedicated support hotline for troubleshooting. Customers receive on-site assistance from certified technicians for any operational issues that arise, ensuring minimal downtime. Service contracts can also include preventive maintenance programs tailored to specific needs.

Product Transportation

The HXGN overhead distribution transformer is transported using specialized lifting equipment to ensure safety and prevent damage. Packaging is designed to withstand environmental stressors, with moisture-proof and shock-resistant materials used. Products are shipped in compliance with international logistic standards and include real-time tracking for customer convenience.

Product Advantages

- Cost-Effectiveness: Offers a lower installation cost compared to underground systems.

- Ease of Access: Facilitates quicker maintenance and repairs.

- Flexibility: Easily expanded to meet growing demand.

- Reliability: Advanced technology ensures stable operation.

Product FAQ

What voltage levels can the HXGN transformer handle?

Our HXGN overhead distribution transformers are designed to handle medium voltage levels ranging from 3kV to 10kV, efficiently stepping down to 120/240V or 480V for safe distribution to end users.

What materials are used in your transformers?

As a manufacturer, we use high-grade silicon steel for the core and copper or aluminum for the windings, ensuring high efficiency and minimal energy loss.

How does the transformer perform under extreme weather conditions?

The transformer is encased in a weather-resistant shell, making it robust against various environmental conditions, including high winds, rain, and extreme temperatures.

What is the lifespan of the HXGN transformer?

With proper maintenance, our transformers have an estimated lifespan of 20 to 30 years, provided they operate under standard load conditions.

Are your transformers environmentally friendly?

Yes, we utilize eco-friendly insulating fluids and comply with environmental standards, minimizing the ecological impact of each unit.

What kind of maintenance is required?

Regular inspections and testing are recommended to ensure peak performance. Our service team offers comprehensive maintenance plans tailored to individual customer needs.

Can the transformers handle overload conditions?

Our transformers are designed with a margin for occasional overloads, but sustained overloads should be avoided to prevent undue stress on the system.

Do you provide installation services?

Yes, professional installation services are available, ensuring that each transformer is setup and integrated properly into your existing power network.

Are the transformers compatible with renewable energy sources?

Yes, our transformers can seamlessly integrate with renewable energy systems, like solar or wind, adapting to varying input levels without compromising efficiency.

How do you ensure transformer safety during transportation?

Each transformer is securely packaged using reinforced materials, and we follow strict international transport regulations to prevent damage during shipping.

Product Hot Topics

How is the efficiency of an overhead distribution transformer determined?

The efficiency of an overhead distribution transformer is determined by its ability to minimize energy losses during voltage conversion. This involves evaluating the performance of the silicon steel core and copper or aluminum windings. As a leading manufacturer, we ensure that each transformer undergoes rigorous testing to ensure peak efficiency. Factors like core material, winding configuration, and insulation quality play crucial roles in performance metrics, making it essential to optimize design and material selection. Continuous advancements in technology have led to more sophisticated transformer designs, further enhancing their energy-conversion efficiency.

What are the environmental considerations in transformer design?

Environmental considerations are paramount in the design and manufacture of transformers. From using eco-friendly insulating fluids to implementing designs that minimize electromagnetic interference, manufacturers strive to align their products with environmental sustainability goals. Techniques such as smart sensor integration for real-time monitoring and predictive maintenance help in reducing energy waste and environmental impact. As leading manufacturers, we prioritize minimizing the carbon footprint of our transformers while ensuring robust performance, making these considerations integral to our R&D efforts.

Image Description