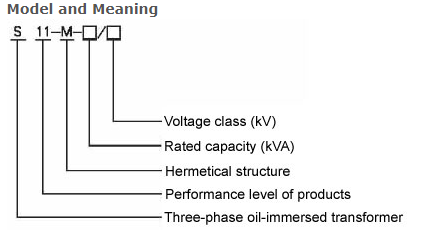

Factory-Made Oil Filled Pad Mounted Transformer

Product Main Parameters

| Parameter | Specification |

|---|---|

| Phase | Three |

| Service Voltage | 6-35kV |

| Rated Capacity | 30-10000kVA |

Common Product Specifications

| Type | Rated Capacity (KVA) | Voltage Combination (KV) | No-load Losses (W) |

|---|---|---|---|

| S11 | 30 | 6.3-11 | 100 |

| S11 | 50 | 10.5-11 | 130 |

Product Manufacturing Process

The manufacturing of factory-made oil filled pad mounted transformers involves a series of precise engineering steps. Initially, high-quality steel is used to construct the robust enclosure. The core and coil assemblies are meticulously designed and wound, ensuring minimal electrical losses. These components are then immersed in refined insulating oil, tested for its dielectric strength. The assembly undergoes rigorous quality checks, including pressure and thermal testing, to ensure its reliability and efficiency in power distribution. Such thorough inspection processes align with findings in authoritative industry papers, highlighting the critical role of quality control in transformer longevity and performance.

Product Application Scenarios

Factory-made oil filled pad mounted transformers are extensively utilized in multiple environments. Their primary role is in urban and suburban areas, facilitating the distribution of electricity across residential complexes, commercial establishments, and light industrial parks. According to leading studies, these transformers' design, which allows for ground-level maintenance, offers significant advantages in terms of accessibility and safety. Furthermore, scholarly articles emphasize the importance of these transformers in minimizing visual pollution in populated areas, thus offering both aesthetic and functional benefits.

Product After-Sales Service

Our dedicated after-sales service ensures that customers receive comprehensive support, including installation guidance and maintenance tips. A professional team is available for troubleshooting and technical assistance, ensuring product longevity.

Product Transportation

Transportation of the factory-made oil filled pad mounted transformer is conducted using specialized equipment to prevent damage. Each unit is carefully packaged to withstand transit conditions, ensuring it arrives at its destination in optimal condition.

Product Advantages

- Robust and weather-proof design for increased longevity.

- Efficient heat dissipation using advanced cooling techniques.

- Environmentally friendly production with focus on sustainability.

- Easy maintenance due to ground-level installation.

- Enhanced safety features with tamper-proof enclosures.

Product FAQ

- What is the lifespan of the transformer? The factory-made oil filled pad mounted transformer has a typical lifespan of around 25-30 years, assuming regular maintenance and inspections are performed to uphold operational integrity.

- How does the cooling system work? The cooling system in our transformers utilizes mineral oil or eco-friendly alternatives, with external radiators or fins enhancing heat dissipation, maintaining optimum operating temperatures.

- Why choose factory-made oil filled pad mounted transformers? These transformers offer reliability, safety, and efficiency, making them ideal for diverse electrical distribution needs across various sectors.

- Can this transformer be used in extreme environments? Yes, the construction and materials are designed to withstand a range of temperature and humidity conditions, providing reliable service in most climates.

- What are the environmental precautions? Our transformers use environmentally safe oils and include containment systems to prevent leaks, aligning with modern ecological standards.

- How is the transformer installed? The transformer is mounted on a concrete pad, requiring careful positioning and securing to ensure stability and safety during operation.

- What kind of maintenance is required? Regular inspections and oil testing are recommended to ensure the transformer's components are functioning correctly and to prevent potential failures.

- How does it enhance energy efficiency? With reduced no-load and load losses, these transformers ensure energy efficiency, contributing to significant cost savings over time.

- Is remote monitoring available? Yes, integrating modern sensors and IoT technology allows for remote monitoring and management, enhancing operational efficiency.

- What safety certifications does the transformer have? Our transformers comply with various national and international safety standards, including GB and IEC certifications, ensuring the highest safety and performance levels.

Product Hot Topics

- Efficiency in Modern Electrical Systems As electrical systems evolve, the need for efficient power distribution increases. These factory-made oil filled pad mounted transformers provide the necessary efficiency, reducing power loss and operational costs. Their role in ensuring seamless energy supply in urban environments is pivotal, allowing for sustainable growth and development.

- Environmental Impact and Sustainability Minimizing ecological footprints is essential in today's energy landscape. Our transformers meet this demand by utilizing sustainable materials and technologies, aligning with global sustainability goals. The transformers' design reduces environmental risks and supports eco-friendly practices within the energy sector.

- Technological Advancements in Transformer Design Continuous advancements in transformer technology have led to improved designs. Factory-produced oil filled pad mounted transformers capitalize on these improvements, integrating features that enhance performance, reliability, and safety. These technological upgrades ensure that transformers meet the increasing energy demands efficiently.

- Safety Features for Urban Installations Safety is paramount when installing transformers in densely populated areas. Our transformers' tamper-proof enclosures and robust materials provide essential safety features, preventing accidents and ensuring reliability. Such measures are crucial for public safety and infrastructure reliability.

- Cost-Effective Energy Solutions With energy costs on the rise, efficient transformers are key to reducing expenses. Our factory-made oil filled pad mounted transformers offer economical solutions, balancing performance with cost-effectiveness. This approach benefits utilities and consumers alike, making energy more accessible and affordable.

- Adaptability to Diverse Environmental Conditions Operating in varied climatic conditions requires adaptable solutions. The durable construction and advanced materials used in our transformers ensure performance stability across diverse environments, making them ideal for global deployment and infrastructure development.

- Future-Proofing Energy Infrastructure Preparing for future energy demands requires robust infrastructure investments. Our transformers are designed for longevity and adaptability, ensuring they remain relevant and functional as energy systems evolve. This future-proofing is essential for sustainable energy planning.

- Customer-Centric Design and Support Understanding customer needs is crucial in transformer design. Our factory-made transformers reflect this focus, with features and support that prioritize user-friendly operation and maintenance. Our commitment to customer satisfaction ensures lasting partnerships and reliable service.

- The Role of Transformative Technology in Energy As transformative technologies reshape the energy sector, our transformers incorporate these innovations to enhance efficiency and performance. This technological integration ensures that our products remain at the forefront of energy solutions, offering cutting-edge capabilities.

- Energy Security and Reliability Reliable energy distribution is essential for economic stability and growth. Our factory-produced transformers play a critical role in guaranteeing energy security, providing consistent and dependable power delivery, crucial for modern societies and their infrastructures.

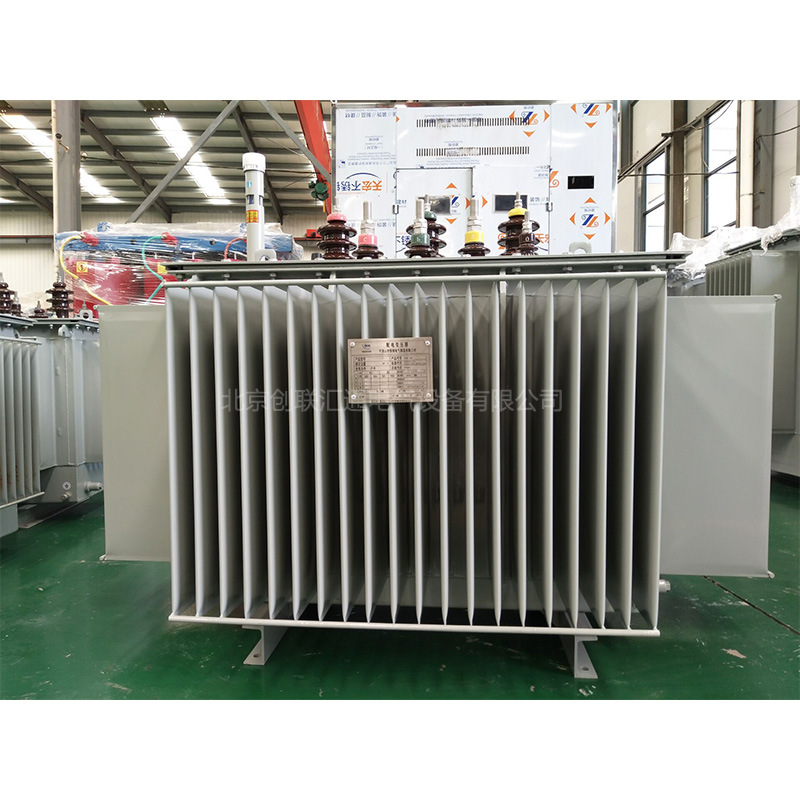

Image Description