Product Main Parameters

| Parameter | Unit | Value |

|---|---|---|

| System Voltage | kV | 40.5 |

| Rated Current | A | 1250, 1600, 2000 |

| Rated Frequency | Hz | 50/60 |

Common Product Specifications

| Specification | Unit | Value |

|---|---|---|

| Lightning Withstand Voltage | kV | 185 |

| Short-Circuit Breaking Current | kA | 20/25/31.5 |

Product Manufacturing Process

Manufacturing high voltage (HV) switchgear like the KYN61-40.5(Z) involves several stages: design, material selection, fabrication, assembly, testing, and quality assurance. The process begins with precise engineering designs using CAD software to ensure accuracy. Materials are chosen based on durability, conductivity, and insulation properties, primarily copper, aluminum, and specialized insulating materials. Fabrication involves cutting, shaping, and assembling these materials into switchgear components such as busbars and circuit breakers. Assembly requires skilled labor to integrate these components into a holistic system, followed by rigorous testing under different electrical loads to ensure safety and functionality. Quality assurance protocols are then applied to meet international electrical standards, ensuring each unit's reliability and efficiency.

Product Application Scenarios

The KYN61-40.5(Z) HV switchgear is widely used across various sectors to ensure the reliable distribution of electricity. In power plants and substations, it controls and protects the electrical systems, preventing faults and interruptions in service. Its application extends to renewable energy sectors like solar and wind, where it stabilizes and manages power flows. Industrial sectors, including petrochemical and manufacturing plants, rely on it for safety and control in high-voltage environments. Additionally, it's instrumental in rail transit systems and urban infrastructure, where power reliability is critical for continuous operations.

Product After-Sales Service

Our comprehensive after-sales service for HV switchgear includes regular maintenance checks, spare parts availability, and technical support. A team of experienced engineers is ready to assist with installation, troubleshooting, and upgrades to maximize product lifespan and efficiency.

Product Transportation

HV switchgear like the KYN61-40.5(Z) is transported using specialized packaging to prevent damage. Shock-absorbent packaging and moisture barriers are employed, and logistics partners are selected for their expertise in handling high-value electrical equipment to ensure safe delivery.

Product Advantages

- High reliability for continuous power system operation.

- Compact design suitable for space-limited environments.

- Low maintenance requirements reduce operational costs.

- Manufactured in our state-of-the-art factory ensuring top quality.

- Meets international standards for safety and performance.

Product FAQ

- What are the primary applications of KYN61-40.5(Z) switchgear? In our factory, we produce HV switchgear types like KYN61-40.5(Z) that are mainly used in power plants, substations, and various industrial sectors for power distribution and protection.

- How does this switchgear improve electrical safety? The KYN61-40.5(Z) is designed to interrupt fault currents, protecting equipment and enhancing electrical safety, a crucial aspect of all HV switchgear types manufactured in our factory.

- What maintenance is required? Factory guidelines for HV switchgear types suggest regular inspections, cleaning, and testing to ensure optimal performance and safety.

- Is the switchgear suitable for outdoor use? While our factory primarily designs HV switchgear types like KYN61-40.5(Z) for indoor use, modifications can be made for specific outdoor applications.

- What is the lifespan of this switchgear? Our factory ensures that HV switchgear types, including KYN61-40.5(Z), meet industry standards for durability, with a typical lifespan exceeding 20 years with proper maintenance.

- How does the switchgear integrate with smart grids? Built at our factory, our HV switchgear types incorporate digital technology for seamless integration with modern smart grid systems.

- Does the switchgear support renewable energy? Yes, these HV switchgear types from our factory support the integration of renewable energy sources, ensuring efficient power management.

- Can the switchgear be customized? Our factory offers customization options for HV switchgear types, adapting designs to meet specific client requirements.

- What protection standards does the switchgear meet? Factory-produced HV switchgear types like KYN61-40.5(Z) comply with IEC standards for electrical safety and performance.

- Is technical support available internationally? Technical support for our factory's HV switchgear types is available globally, ensuring reliable operations across all regions.

Product Hot Topics

- Discussing the integration of HV switchgear types into smart grids is a hot topic, particularly the role our factory plays in advancing these technologies. Integrating HV switchgear, such as our factory's KYN61-40.5(Z), into smart grids allows for enhanced monitoring, control, and optimization of electricity distribution. Smart grids benefit from the digital capabilities built into our switchgear, offering real-time data and predictive maintenance alerts that ensure reliability and reduce downtime.

- The environmental impact of HV switchgear types is a growing concern in the industry. Our factory is committed to sustainable practices, including reducing the carbon footprint of HV switchgear production. By utilizing materials with lower environmental impact and innovating in product design for lifespan extension, our factory contributes to environmentally responsible power solutions.

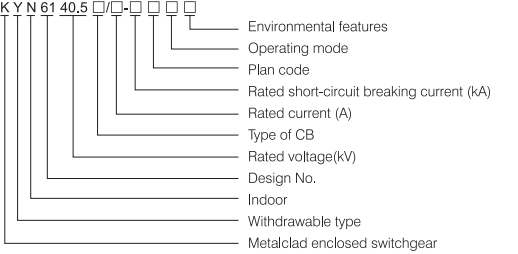

Image Description