Factory-Grade Immersed Transformer for Efficient Power

Product Main Parameters

| Type | Rated Capacity (KVA) | Voltage Combination (KV) | No-load Losses (W) | Load Losses (W) |

|---|---|---|---|---|

| S11 | 30 | 6,6.3,10,10.5,11 | 100 | 600 |

| S11 | 50 | 6,6.3,10,10.5,11 | 130 | 870 |

Common Product Specifications

| Highest Temperature | 40°C |

|---|---|

| Lowest Temperature | -25°C |

| Altitude | <4000 m |

Product Manufacturing Process

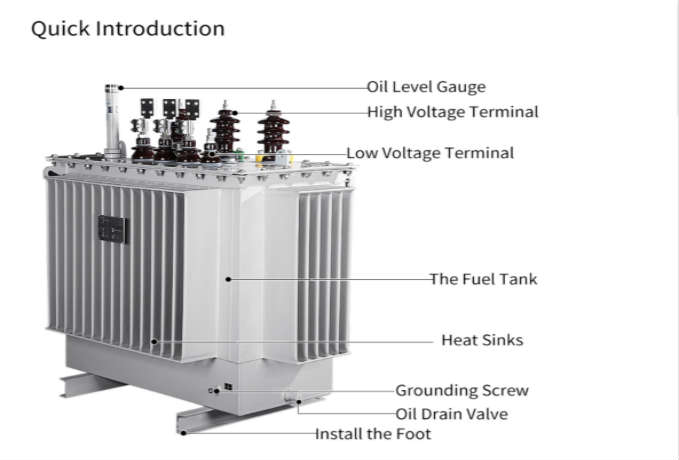

The manufacturing of immersed transformers involves precise engineering and state-of-the-art technology. According to authoritative sources, the process begins with the design of the core, typically constructed from high-grade laminated silicon steel sheets to minimize energy losses. The windings, made from copper or aluminum, are carefully wrapped around the core to ensure effective magnetic flux. Once the core and windings are assembled, they are placed in a sealed tank filled with insulating oil. This oil provides cooling, insulation, and protection from oxidation. The tank is equipped with a conservator to accommodate oil expansion and contraction, which prevents moisture ingress. Continuous quality checks are carried out throughout the manufacturing process to ensure the transformers meet international standards like IEC/60076, guaranteeing their reliability and efficiency in diverse applications.

Product Application Scenarios

Immersed transformers play a vital role in various application scenarios. One primary application is in power distribution, where they step down voltage levels to ensure safe and efficient power delivery to consumers. In industrial facilities, these transformers are critical for powering machinery and maintaining operational continuity. The role of immersed transformers in renewable energy is equally significant. As sustainable energy sources like wind and solar gain prominence, these transformers are essential for managing power output and integrating with the grid, ensuring stability and reliability in energy supply. Research suggests that their cooling efficiency and enhanced insulation properties make them ideal for high-load environments, improving energy efficiency and reducing operational costs.

Product After-Sales Service

Our factory offers comprehensive after-sales service for all immersed transformers, including technical support, maintenance, and warranty repairs. Our team of experts is available to assist with installation, troubleshooting, and performance optimization, ensuring long-term reliability and efficiency. We prioritize customer satisfaction by providing timely and effective solutions to any issues that may arise, fostering strong and enduring partnerships with our clients.

Product Transportation

Transportation of our factory-produced immersed transformers is conducted with utmost care, utilizing secure packaging and specialized transport vehicles to prevent damage during transit. We ensure timely and safe delivery to our global clientele, with logistics planning tailored to meet specific customer requirements. Our commitment to quality extends beyond manufacturing, as we work with trusted logistics partners to guarantee the seamless arrival of our products to their destinations.

Product Advantages

- Cooling Efficiency: The factory-produced immersed transformer utilizes an insulating fluid for effective heat dissipation, ensuring efficient operation even at high loads.

- Enhanced Insulation: The oil offers superior insulation, reducing the risk of electrical faults and enhancing the transformer's safety and reliability.

- Durability: Our factory-made transformers are designed to prevent moisture ingress and oxidation, extending their service lifespan.

FAQs

- What is the lifespan of a factory-immersed transformer?

Our factory-immersed transformers are designed with durability in mind, typically offering a lifespan of 20-30 years, depending on operational conditions and maintenance. - How do you ensure the quality of your immersed transformers?

Quality is assured through rigorous testing and adherence to international standards during each manufacturing step, ensuring high reliability and performance.

Hot Topics

- Why Choose Factory-Produced Immersed Transformers?

Choosing factory-produced immersed transformers ensures access to advanced technology and rigorous quality control, leading to high-efficiency, reliable power distribution solutions for various industrial applications. - Environmental Impact of Immersed Transformers

There is ongoing discussion regarding the environmental footprint of immersed transformers, particularly concerning the insulating fluids used. Our factory is focused on developing alternative fluids that are eco-friendly without compromising performance, contributing to a sustainable energy future.

Image Description