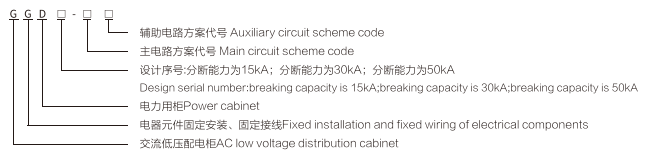

Product Main Parameters

| Model | Rated Voltage (V) | Rated Current (A) | Breaking Current (KA) |

|---|---|---|---|

| GGD1 | 380 | 1000 | 15 |

| GGD2 | 380 | 1600 | 30 |

| GGD3 | 380 | 3150 | 50 |

Common Product Specifications

| Component | Details |

|---|---|

| Material | 8MF cold-formed steel |

| Protection Level | High |

| Temperature Range | -5°C to 40°C |

Product Manufacturing Process

The manufacturing process of HV LV switchgear involves precision engineering to meet international standards. The use of advanced fabrication techniques and high-quality materials ensures that each unit is durable and reliable. The production process is thoroughly monitored for quality control, from initial design and material selection to fabrication, assembly, and testing. Such rigorous standards ensure that the final product not only meets but exceeds customer expectations for performance and safety. Continuous improvement and innovation are key drivers in the manufacturing process, incorporating latest technologies for efficiency and sustainability in power distribution.

Product Application Scenarios

HV LV switchgear is critical in various application scenarios, including power plants, substations, industrial complexes, and commercial buildings. Designed to efficiently distribute electrical power, these systems are integral in environments requiring robust control and protection of electrical networks. Their adaptability allows seamless integration in existing infrastructure, ensuring reliability and safety in power distribution across high and low voltage contexts. Recent studies highlight their essential role in optimizing energy consumption and enhancing the safety of electrical systems, making them indispensable in modern power distribution solutions.

Product After-Sales Service

Our after-sales service includes comprehensive support through installation, operation, and ongoing maintenance. Customers benefit from expert technical assistance, quick response times, and access to original spare parts, ensuring uninterrupted service and minimal downtime.

Product Transportation

Products are securely packaged using industry-standard materials to prevent damage during transportation. Our logistics team ensures timely delivery, catering to domestic and international shipments with complete tracking and customer communication.

Product Advantages

- Advanced technology for high efficiency.

- Robust construction ensures durability and reliability.

- Factory-direct pricing offers cost-effective solutions.

- Versatile applications across industrial and residential sectors.

- Comprehensive after-sales support enhances user experience.

Product FAQ

- What is HV LV switchgear?

HV LV switchgear is used to distribute electrical power safely and efficiently, integrating high and low voltage control equipment within a factory setting for optimal performance.

- What applications are suitable for this switchgear?

It's suitable for factories, industrial plants, and commercial buildings where reliable power distribution is crucial.

- How is the quality of the switchgear ensured?

Through stringent manufacturing processes and quality control measures, ensuring the switchgear meets high industry standards.

- Does this switchgear meet international standards?

Yes, it complies with IEC and GB standards for safety and performance.

- Can the switchgear be customized?

Yes, customization is available to meet specific factory requirements and application needs.

- What is the expected lifespan of the switchgear?

Designed for a long service life with minimal maintenance, supported by robust construction and advanced technology.

- How is the switchgear transported?

Transportation follows secure packaging standards to prevent damage, with logistics support for efficient delivery.

- What after-sales services are provided?

Comprehensive support is provided, including installation, operation guidance, and maintenance assistance.

- What materials are used in manufacturing?

High-quality materials such as 8MF cold-formed steel ensure durability and reliability in performance.

- How does the switchgear enhance safety?

Incorporating advanced protection features and automation, it ensures safety in electrical distribution within a factory setting.

Product Hot Topics

- Innovation in HV LV Switchgear: The Future of Power Distribution

The future of HV LV switchgear in factories involves integrating smart technologies to enhance efficiency and adaptability. Recent developments focus on automation and IoT, allowing real-time monitoring and control for optimized performance. As power systems evolve, so too does the demand for smart switchgear solutions that offer enhanced safety and operational efficiency in diverse industrial settings.

- Challenges in Implementing HV LV Switchgear in Factories

Implementing HV LV switchgear in factory settings poses various challenges, including overcoming existing infrastructure constraints and adapting new technologies for seamless integration. Despite these hurdles, ongoing research and development efforts focus on creating versatile solutions that can be customized for specific applications, ensuring efficiency and safety in power distribution systems.

- Sustainability and Efficiency: The Role of HV LV Switchgear

Sustainability in factories is increasingly important, and HV LV switchgear plays a pivotal role in achieving energy efficiency. By optimizing power distribution and incorporating energy-saving technologies, modern switchgear solutions help factories reduce their carbon footprint and operate sustainably without compromising on performance or safety.

- Advancements in HV LV Switchgear Design and Technology

Recent advancements in HV LV switchgear design enhance flexibility and efficiency in power distribution within factories. Innovations focus on robust construction and smart technology integration, providing reliable solutions that cater to evolving energy demands. These advancements ensure that factories can achieve seamless and safe electrical distribution in complex industrial environments.

- Integration of HV LV Switchgear in Modern Industrial Systems

The integration of HV LV switchgear in modern industrial systems involves combining cutting-edge technology with traditional power distribution equipment. This integration enhances the reliability and safety of electrical systems in factories, ensuring optimal performance across various voltage levels while accommodating future growth and technological advancements.

- The Impact of Digitalization on HV LV Switchgear

Digitalization has significantly impacted HV LV switchgear, transforming it into an integral component of smart factory systems. Enhanced connectivity and data analytics capabilities provide real-time insights into power distribution, enabling better decision-making and improved operational efficiency in complex industrial environments.

- Ensuring Safety and Reliability with HV LV Switchgear

Safety and reliability are paramount with HV LV switchgear in factory applications. Advanced safety mechanisms and automation features protect both personnel and equipment. Implementing updated safety standards and regular maintenance ensures long-term reliability in power distribution systems.

- The Economic Benefits of Using HV LV Switchgear in Factories

Incorporating HV LV switchgear in factories offers significant economic benefits, including reduced downtime, lower maintenance costs, and efficient energy distribution. These advantages contribute to increased productivity and profitability, making switchgear an essential component of modern industrial infrastructure.

- Customization Options for HV LV Switchgear in Industrial Applications

Customization options for HV LV switchgear allow factories to tailor solutions to meet specific operational requirements. Whether it's adapting to space constraints or enhancing functionality with additional features, customizable switchgear provides the flexibility needed to optimize power distribution in diverse industrial settings.

- The Role of HV LV Switchgear in Energy Transition

As factories transition towards greener energy solutions, HV LV switchgear aids in facilitating this shift by enabling efficient integration of renewable energy sources. By managing power distribution effectively, switchgear ensures that factories can maintain operational efficiency while reducing their environmental impact.

Image Description