Product Main Parameters

| Parameter | Details |

|---|---|

| Rated Capacity | 30-10000 kVA |

| Service Voltage | 6-35kV |

| Phase | Three |

| Brand Name | ZHONGHAO |

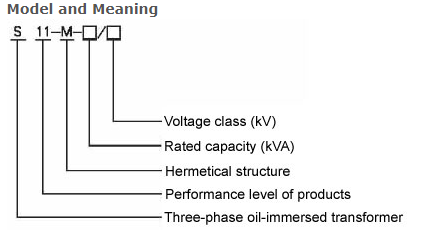

| Model Number | S11 |

Common Product Specifications

| Type | Rated Capacity (KVA) | No-load losses (W) | Load losses (W) | No-load current (%) | Short-circuit impedance (%) |

|---|---|---|---|---|---|

| S11 | 30 | 100 | 600 | 2.3 | 4.0 |

| S11 | 50 | 130 | 870 | 2.0 |

Product Manufacturing Process

The manufacturing process of dry resin transformers in our factory involves precise steps ensuring high-quality standards. The copper or aluminum windings are carefully encapsulated in epoxy resin using advanced vacuum pressure technology. This process ensures excellent insulation and mechanical protection, significantly reducing energy losses and enhancing the durability of the transformers. A rigorous quality control system is implemented at each stage to maintain product reliability and consistency. As concluded in recent studies, this approach maximizes transformer efficiency and extends operational life while minimizing maintenance costs.

Product Application Scenarios

Factory-built dry resin transformers are ideally suited for a range of applications due to their safety and environmental benefits. They are extensively used in commercial and residential buildings where space and fire safety are critical. Their robust design makes them suitable for industrial facilities exposed to dust, moisture, or corrosive conditions as well. Increasingly, these transformers are being integrated into renewable energy systems like wind farms and solar power installations. This adaptability to various environments confirms findings from authoritative studies, emphasizing the transformative potential of dry resin transformers in energy distribution networks.

Product After-Sales Service

Our factory provides comprehensive after-sales service for dry resin transformers, including technical support, maintenance guidance, and warranty coverage. Our dedicated team ensures prompt resolution of any issues to guarantee customer satisfaction.

Product Transportation

Dry resin transformers are securely packaged and transported to minimize transit damage. Our factory coordinates with reliable logistics partners to ensure timely delivery to clients worldwide.

Product Advantages

- Improved Safety: Fire-resistant design suitable for indoor installations.

- Environmental Sustainability: No risk of oil leaks, safeguarding ecosystems.

- Low Maintenance: Simplifies operational requirements compared to oil-filled variants.

- Space Efficiency: Adaptable to confined environments, enhancing installation flexibility.

Product FAQ

- What is a dry resin transformer? A dry resin transformer is a type of transformer where windings are encapsulated in resin, offering enhanced safety and reduced maintenance requirements.

- How does a factory-built dry resin transformer improve safety? It mitigates fire risks by eliminating oil, making it suitable for indoor and vulnerable installations.

- Why choose a dry resin transformer over an oil-filled one? Dry resin transformers are environmentally friendly, require less maintenance, and are safer for certain applications.

- What is the lifespan of a dry resin transformer? With proper maintenance, dry resin transformers can last several decades due to their durable construction.

- In what industries can dry resin transformers be used? They are versatile, suitable for commercial, residential, industrial, and renewable energy sectors.

- Are dry resin transformers eco-friendly? Yes, they eliminate oil spill risks and offer a sustainable alternative to oil-filled transformers.

- Is transportation a concern for dry resin transformers? No, our factory ensures secure packaging and reliable delivery to minimize transport concerns.

- How does our factory ensure product quality? We follow stringent quality control measures through every manufacturing stage, ensuring high standards.

- What maintenance do dry resin transformers require? Minimal maintenance is needed, primarily regular inspections to ensure optimal functioning.

- Can dry resin transformers handle high capacities? While suited for medium to low capacities, advancements continue to expand their range of applications.

Product Hot Topics

- The Role of Factory-Built Dry Resin Transformers in Modern Infrastructure As urban environments grow, the need for safe and space-efficient power solutions becomes critical. Factory-built dry resin transformers fulfill these needs by providing reliable and compact energy distribution without compromising on safety.

- Environmental Impact of Dry Resin Transformers Unlike traditional options, dry resin transformers minimize ecological threats. Their use of resin over oil significantly reduces environmental risks, aligning with global sustainability goals and reducing the carbon footprint of energy infrastructure.

- Advancements in Dry Resin Transformer Technology Ongoing research continues to improve the materials and efficiencies of dry resin transformers, positioning them as a forward-thinking choice for power systems looking to integrate modern technology into distribution networks.

- Integration of Dry Resin Transformers in Renewable Energy Systems As the energy sector shifts towards sustainable sources, dry resin transformers offer the flexibility and reliability needed for integrating wind and solar power into the grid, supporting cleaner energy transition efforts.

- Comparative Analysis: Oil-filled vs Dry Resin Transformers While oil-filled transformers have been traditional choices, many industries now lean towards dry resin solutions due to their superior safety profile and reduced maintenance needs.

- Cost Analysis of Dry Resin Transformers Over Time Despite higher initial costs, dry resin transformers often deliver better value due to lower operational expenses, proving economically viable over their lifespan.

- Understanding the Manufacturing Process of Dry Resin Transformers Factory processes ensure that each dry resin transformer is meticulously crafted, delivering high-quality performance and reliability to meet various operational demands.

- Challenges and Solutions in Dry Resin Transformer Deployment While there are challenges in deployment, such as cooling limitations, advances in design and technology continuously improve their adaptability and performance in diverse conditions.

- Customer Experiences with Factory-Built Dry Resin Transformers Many clients report satisfaction with their performance, citing their adaptability, low maintenance needs, and robust construction as key advantages over traditional power systems.

- Future Prospects for Dry Resin Transformers in Global Markets As power needs continue evolving, dry resin transformers are poised to capture significant market share, driven by technological innovations and the global push towards sustainable energy systems.

Image Description