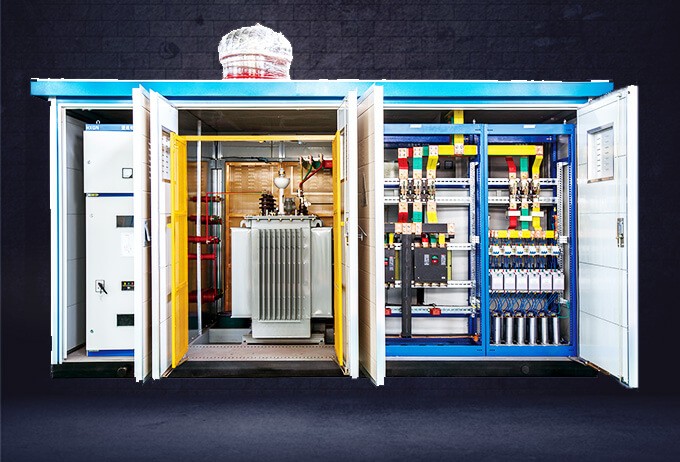

Factory-Built Auxiliary Transformer in Substation

Product Main Parameters

| Parameter | Value |

|---|---|

| Rated Voltage | 40.5 kV |

| Rated Power | 1250-20000 kVA |

| Frequency | 50 Hz |

Common Product Specifications

| Specification | Detail |

|---|---|

| Operating Temperature | -25℃ to 40℃ |

| Humidity | Monthly avg. ≤ 90% |

| Installation Site | No fire/explosion hazards |

Product Manufacturing Process

The manufacturing process of auxiliary transformers for substations includes advanced engineering techniques to ensure high reliability and efficiency. According to the latest papers, the process begins with high-grade materials selection, followed by precision core building and winding coil technology. With computer-aided design and automated assembly, the transformers are subjected to rigorous testing against international standards. The transformers are designed to withstand harsh environmental conditions, contributing to their robust performance in varying substation scenarios.

Product Application Scenarios

Auxiliary transformers are crucial in substations for maintaining operational stability. They provide power to lighting, relay protection, and control systems within the substation. Studies highlight their role in supporting renewable energy integration within substations, enhancing smart grid capabilities. These transformers ensure seamless operation during maintenance or faults, contributing to reliable power distribution.

Product After-Sales Service

Our factory offers comprehensive after-sales services including installation assistance, regular maintenance, and 24/7 customer support for auxiliary transformers in substations. Clients benefit from extended warranties and periodic inspections to ensure prolonged product lifespan and efficiency.

Product Transportation

We ensure factory-to-site transportation is efficient and safe. Auxiliary transformers for substations are securely packed and shipped using reliable logistics partners, minimizing transit damage and ensuring timely delivery to client facilities.

Product Advantages

- High Efficiency: Ensures optimal power management within substations.

- Durability: Designed to withstand harsh environments.

- Cost-Effective: Reduces maintenance and operational costs.

Product FAQ

- What is the primary role of an auxiliary transformer in a substation? An auxiliary transformer provides power to the substation's internal systems, ensuring operational stability.

- How does the factory ensure the quality of these transformers? Our factory employs stringent quality control measures and advanced testing procedures to guarantee superior performance and reliability.

- Can auxiliary transformers support renewable energy integration? Yes, they are compatible with smart grid technologies and renewable energy sources.

- What maintenance is required for auxiliary transformers? Routine inspections, oil testing, and thermal imaging are recommended to maintain performance.

- Are these transformers suitable for outdoor installation? Yes, oil-filled types are designed for durable outdoor use.

- How does the factory manage customization requests? We offer tailored solutions to meet specific substation requirements, backed by our expert R&D team.

- What happens if there is a fault in the transformer? Built-in protection systems and regular maintenance reduce fault risks, ensuring reliability.

- How does the transformer handle voltage variations? It efficiently manages voltage conversions to maintain grid stability.

- Is technical support available during installation? Yes, our team provides on-site support and guidance.

- What makes these transformers environmentally friendly? We use sustainable materials and energy-efficient designs to minimize environmental impact.

Product Hot Topics

- Integration of Smart Technologies in Substations With the rise of smart grids, auxiliary transformers are evolving to support advanced technological requirements, ensuring compatibility with modern grid infrastructures.

- The Role of Auxiliary Transformers in Renewable Energy Substations As the global shift towards renewable energy grows, auxiliary transformers facilitate efficient energy management within substations, enabling seamless integration of solar and wind power sources.

- Enhancing Substation Safety with Reliable Auxiliary Transformers Safety is paramount in power systems; auxiliary transformers play a critical role in maintaining uninterrupted power for essential control and safety equipment.

- Cost-effectiveness of Factory-Designed Auxiliary Transformers By leveraging in-factory innovation, the design and production of auxiliary transformers offer significant cost advantages, reducing overall operational expenses for substations.

- Durability and Performance in Extreme Conditions Auxiliary transformers are engineered to endure harsh environmental conditions, providing sustained performance and reliability in all climates.

- Advancements in Transformer Manufacturing Processes The use of cutting-edge technology in manufacturing processes enhances the efficiency and reliability of auxiliary transformers.

- Impact of Technological Developments on Transformer Design Ongoing R&D efforts lead to continuous improvements in transformer design, optimizing efficiency and performance while meeting evolving industry standards.

- Future Trends in Substation Auxiliary Systems Innovations in materials and design are paving the way for next-generation auxiliary transformers, focusing on sustainability and energy efficiency.

- Global Demand and Supply of Auxiliary Transformers The market for auxiliary transformers continues to expand globally, driven by increased investment in power infrastructure and renewable energy projects.

- The Importance of Routine Maintenance and Inspections Regular maintenance protocols are essential for ensuring the longevity and effective operation of auxiliary transformers in substations.

Image Description