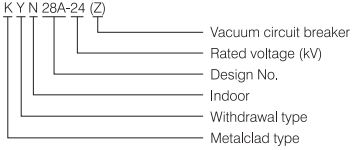

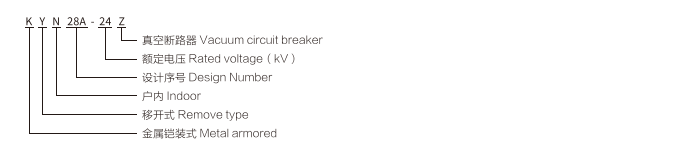

Dependable Supplier of Auxiliary Transformers: KYN28A-24

Product Details

| Parameter | Values |

|---|---|

| Rated Voltage | 24kV |

| Rated Frequency | 50/60Hz |

| Rated Current | 630, 1250, 1600, 2000, 2500, 3150 A |

| Short-Circuit Breaking Current | 20, 31.5 kA |

| Protection Level | IP4X |

| Dimensions | 800×1810×2380 mm |

Product Manufacturing Process

The manufacturing process for auxiliary transformers like the KYN28A-24 involves several meticulous steps to ensure durability, reliability, and efficiency. Initially, the core and winding materials are selected based on stringent quality standards. The core is constructed using laminated silicon steel for optimal magnetic properties. Windings are then meticulously wound and insulated to prevent electrical breakdowns. The components are assembled in a controlled environment to maintain precision. Final assembly includes rigorous testing for performance parameters like voltage and current ratings. These processes align with international standards such as IEC 62271-200, ensuring the auxiliary transformers meet or exceed performance expectations in industrial applications. This rigorous process guarantees a high degree of reliability and resilience, making the auxiliary transformers a critical component in power distribution systems.

Product Application Scenarios

Auxiliary transformers are indispensable in scenarios requiring stable power for auxiliary systems within power plants, substations, and industrial settings. In power plants, they supply essential systems such as backup lighting, control systems, and emergency operations, ensuring uninterrupted plant functionality. In substations, they power circuit breakers and control relays necessary for maintaining grid stability and safety. In industrial contexts, they adapt to varying voltage requirements, supporting machinery and equipment operations. This adaptability is pivotal as industries integrate renewable energy sources, demanding auxiliary transformers that support dynamic power conditions. This versatility and reliability underscore the auxiliary transformer's integral role in modern electrical and industrial infrastructure.

Product After-Sales Service

- Comprehensive technical support and troubleshooting.

- Flexible warranty options tailored to client needs.

- Regular maintenance and performance checks.

- Rapid repair and replacement services.

- 24/7 customer service hotline for immediate assistance.

Product Transportation

- Robust packaging to withstand transportation stress.

- Secure logistics network for timely delivery.

- Coordinated shipping with real-time tracking.

- Customized transport solutions for oversized components.

Product Advantages

- High-performance reliability ensures stable auxiliary power supply.

- Optimized design for increased efficiency and reduced operational costs.

- Customizable to meet specific voltage and current needs.

- Compliance with global standards ensures safety and quality.

- Versatile application in diverse industrial sectors.

Product FAQ

- What is the primary function of an auxiliary transformer?

Auxiliary transformers supply power to secondary systems within industrial operations, ensuring stable energy to control, lighting, and HVAC systems. - How does the KYN28A-24 compare to other models?

The KYN28A-24 offers modular design and enhanced safety features, catering to various voltage requirements with high efficiency. - What industries commonly use auxiliary transformers?

Power plants, substations, manufacturing facilities, and any industry requiring stable auxiliary power integrate these transformers for operational efficiency. - Can the KYN28A-24 be customized?

Yes, customization options are available to meet specific voltage, frequency, and application requirements, ensuring optimal performance. - What maintenance is needed for these transformers?

Routine inspections, timely replacement of worn components, and regular testing of electrical parameters are recommended for maintaining efficiency. - What standards does the KYN28A-24 comply with?

It complies with IEC 62271-200, ensuring it meets international safety and performance standards. - How does the auxiliary transformer handle dynamic loads?

Advanced load management technology allows these transformers to adapt efficiently to varying loads and renewable energy integration. - What are the geographical regions served?

The company serves global markets, including Europe, South America, Africa, and Southeast Asia, ensuring widespread availability. - How are transportation and delivery handled?

Robust packaging and secure logistics ensure safe and timely delivery, with options for tracking and customized solutions for large components. - What after-sales support is available?

Comprehensive technical support, flexible warranties, and rapid repair services are available to support customers post-purchase.

Product Hot Topics

- Enhancing Industrial Efficiency with Auxiliary Transformers

Auxiliary transformers are pivotal in boosting operational efficiency across industries. By supplying stable power to secondary systems, they ensure seamless operations and prevent disruptions in control and monitoring systems. In sectors like manufacturing and energy, where precise control and consistent power are vital, reliable auxiliary transformers like the KYN28A-24 prove indispensable. Their adaptability to various voltage and current needs, along with compliance with international standards, makes them a trusted choice globally. As industries evolve, the role of these transformers in enhancing productivity and efficiency continues to grow. - The Role of Auxiliary Transformers in the Energy Transition

As the global focus shifts toward sustainable energy, auxiliary transformers play a crucial role in the integration of renewable sources. The ability to handle dynamic power conditions and support microgrid applications makes them vital in modern power systems. Auxiliary transformers like the KYN28A-24 are designed to adapt to these changing conditions, ensuring that systems remain efficient and reliable. Their contribution to the energy transition is significant, as they facilitate the seamless operation of renewable energy systems, underscoring their importance in future-proofing energy infrastructures. - Customizing Auxiliary Transformers for Specific Industrial Needs

Industries often require tailored solutions to meet specific operational needs. Auxiliary transformers offer the flexibility needed in such instances, allowing for customization in terms of voltage, current, and application requirements. This adaptability ensures that every industry, from petrochemicals to aerospace, can maintain optimal operational efficiency. The KYN28A-24 model exemplifies this capability, providing a robust framework for customization and ensuring industries have reliable power solutions that align with their unique demands. - Addressing Common Challenges with Auxiliary Transformers

While auxiliary transformers are reliable, they can face challenges related to continuous operation and environmental factors. Ensuring robust construction and regular maintenance are key to overcoming these hurdles. Innovative designs like thermal management systems and protective enclosures enhance their durability and resilience. By addressing these common challenges, suppliers of auxiliary transformers ensure long-term efficiency and reliability, essential for industries that depend on uninterrupted power for secondary systems. - Global Reach: Auxiliary Transformers in International Markets

The demand for reliable power solutions extends across global markets, and auxiliary transformers are at the forefront of meeting this need. With a presence in regions such as Europe, South America, Africa, and Southeast Asia, suppliers like Global Power Equipment ensure that high-quality solutions are readily available. This widespread availability, combined with compliance with international standards, ensures that industries worldwide can optimize their operations with reliable auxiliary power, cementing the role of these transformers as a cornerstone in global power distribution. - Ensuring Safety with Auxiliary Transformers

Safety is paramount in power distribution, and auxiliary transformers are equipped with features to uphold this principle. Models like the KYN28A-24 incorporate safety mechanisms against overloading and short circuits, ensuring that operations remain secure. These features not only protect the main infrastructure but also safeguard personnel by minimizing the risk of electrical hazards. As safety standards evolve, the continuous improvement in auxiliary transformer design is crucial in maintaining high safety benchmarks across industries. - Technological Advancements in Auxiliary Transformer Design

Technological innovation drives the evolution of auxiliary transformers, enhancing their performance and efficiency. From improved insulation materials to advanced load management systems, these innovations ensure that transformers remain at the cutting edge of power technology. The integration of smart features and digital monitoring further optimizes their functionality, providing industries with insights into performance metrics and enabling proactive maintenance. These advancements solidify auxiliary transformers as integral components in modern power distribution systems. - New Energy Landscapes and the Adaptability of Auxiliary Transformers

As energy landscapes evolve with greater emphasis on sustainability, auxiliary transformers must adapt to new challenges posed by renewable integration. Their ability to support microgrids and battery storage systems illustrates their versatility in modern power systems. The KYN28A-24, for instance, showcases how auxiliary transformers can seamlessly integrate with these systems, providing reliable power in dynamic conditions. This adaptability highlights their role in supporting diverse energy strategies and ensuring reliable power distribution across varying applications. - The Importance of Quality Assurance in Transformer Production

For auxiliary transformers to perform optimally, stringent quality assurance during production is critical. Comprehensive testing at various stages ensures that each unit meets or exceeds performance standards, preventing operational failures. Suppliers committed to quality, like Global Power Equipment, invest in robust quality control systems that uphold product reliability and performance. This commitment to quality assurance ensures that auxiliary transformers provide consistent, reliable power for industrial operations worldwide. - Future Trends in Auxiliary Transformer Technology

The future of auxiliary transformers is shaped by innovations aimed at enhancing efficiency and integrating smart technologies. Future models will likely incorporate more advanced monitoring systems, allowing for real-time performance analysis and predictive maintenance. Additionally, continued advancements in materials technology will further enhance efficiency and reduce operational costs. As the energy sector evolves, auxiliary transformers will play a pivotal role in facilitating efficient and adaptive power distribution, ensuring they remain at the forefront of technological progress.

Image Description