Product Main Parameters

| Type | Rated Capacity (KVA) | Connection Symbol | Voltage Combination (KV) | No-load Losses (W) | Load Losses (W) | No-load Current (%) | Short-circuit Impedance (%) |

|---|---|---|---|---|---|---|---|

| S11 | 30 | Yyn0 or Dyn11 | 6, 6.3, 10, 10.5, 11 ±5% or ±2×2.5% | 100 | 600 | 2.3 | 4.0 |

Common Product Specifications

| Temperature Range | Altitude | Installation Location |

|---|---|---|

| -25 to 40 °C | < 4000 m | Indoor and outdoor |

Product Manufacturing Process

The manufacturing of China's mains transformers involves precision engineering and stringent quality controls. Using advanced computer-aided design technology, each transformer is constructed with high-grade materials to ensure optimal performance and longevity. The core is typically made of high-permeability silicon steel sheets, while the windings use copper or aluminum to minimize resistive losses. The entire process includes multiple stages of testing, ensuring compliance with both national and international standards such as GB 1094 and IEC 60076. By maintaining rigorous testing protocols, Global Power Equipment ensures each transformer delivers efficiency, reliability, and safety in all operational environments.

Product Application Scenarios

China's mains transformers are integral to a vast range of applications, including power distribution networks, industrial manufacturing, and renewable energy systems. In power distribution, they step down high transmission voltages for safe residential and commercial use. In industrial settings, these transformers support machinery and equipment by providing stable voltage outputs essential for smooth operation. Additionally, they contribute significantly to renewable energy projects by facilitating efficient energy conversion and distribution. Their versatility and reliability have made them indispensable across diverse sectors, ensuring energy systems operate efficiently and safely.

Product After-Sales Service

Global Power Equipment offers comprehensive after-sales support for its China mains transformers, including installation guidance, troubleshooting, and maintenance services. Dedicated customer service teams are available for consultation and support, ensuring clients achieve optimal performance from their transformers.

Product Transportation

Transporting mains transformers requires careful handling to prevent damage. Global Power Equipment ensures that each transformer is securely packaged with protective materials and transported using specialized vehicles to prevent shocks and vibrations during transit.

Product Advantages

- High Efficiency

- Low Noise Operation

- Durable Construction

- Cost-effective

- High Reliability

Product FAQ

Q1: What is the typical lifespan of a China mains transformer?

A1: China's mains transformers are designed for durability, typically lasting 20 to 30 years with proper maintenance. Regular inspections and servicing can extend their operational life significantly.

Q2: Can the transformer operate in extreme weather conditions?

A2: Yes, these transformers are engineered to withstand a wide range of temperatures, from -25°C to 40°C, making them suitable for various climates across China and internationally.

Q3: Is installation complicated?

A3: Installation is straightforward with provided guidelines, and Global Power Equipment offers assistance to ensure safe and proper setup.

Q4: How does this transformer improve energy efficiency?

A4: China's mains transformers reduce energy losses through advanced thermal management and high-quality materials, enhancing overall energy efficiency.

Q5: What safety features are included?

A5: These transformers incorporate safety features like overload protection and thermal sensors to ensure safe and reliable operation.

Q6: Are customization options available?

A6: Global Power Equipment offers customization options to meet specific requirements for voltage, capacity, and application needs.

Q7: How does oil immersion benefit the transformer?

A7: Oil immersion offers superior insulation and cooling, helping to dissipate heat and maintain stable performance in China mains transformers.

Q8: Can the transformer be used in renewable energy applications?

A8: Yes, they are well-suited for renewable energy projects, offering efficient energy conversion and integration capabilities.

Q9: What are the maintenance requirements?

A9: Regular maintenance includes checking oil levels, inspecting connections, and monitoring performance metrics to ensure long-term reliability.

Q10: How does Global Power Equipment ensure quality?

A10: Global Power Equipment employs stringent testing and quality assurance processes aligned with international standards to ensure each transformer meets high-performance criteria.

Product Hot Topics

China's Role in Mains Transformer Innovation

China's advancement in mains transformer technology underscores its commitment to energy efficiency and sustainability. Companies like Global Power Equipment lead this innovation by developing transformers that support both conventional and renewable energy infrastructures. This dedication ensures reliable power distribution system performance both domestically and internationally.

The Impact of Mains Transformers on Global Power Infrastructure

Mains transformers play a crucial role in global power infrastructure, facilitating voltage transformation that makes long-distance electricity transmission possible. China's expertise in transformer manufacturing has enabled efficient and safe power distribution worldwide, highlighting the significance of reliable transformer solutions in modern energy systems.

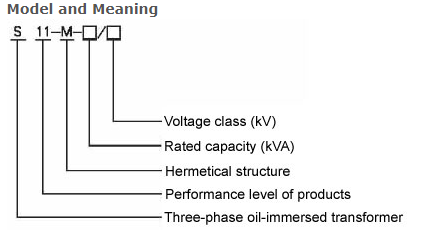

Image Description